The vertical impact drop test, also known as the drop impact test, is suitable for evaluating the impact resistance strength of the transport package when it is subjected to a vertical impact, and the ability of the package to protect the contents. The principle of the drop impact test is to raise the sample to a predetermined height, and then make it fall freely on the impact surface. There are three types of drop methods for packages: surface drop, edge drop and corner drop .

(1) Drop test machine

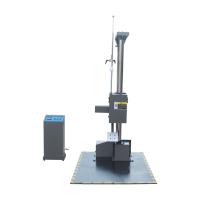

The equipment used in the vertical impact drop test is a drop test machine, which is mainly composed of a lifting device, a support and release device, and an impact surface, as shown in Figure 6-4. The drop test machine is divided into three types: flap type, hook type and swing arm type. The flap structure is relatively complicated, but it is not easy for the two flaps to move synchronously, so it has been eliminated. The hook-type structure is relatively simple and has been used earlier, but it cannot precisely control the falling posture. The swivel arm structure is complex, but it can accurately control the falling posture, and is currently widely used. The impact surface must have a large enough mass, at least 50 times the mass of the package; no displacement can occur during impact; the surface is smooth, and can ensure normal surface drop, edge drop or corner drop; hard, no deformation during impact; yes Enough area to ensure that the sample falls completely on the impact surface during impact.

Figure 6-4 Rotary Arm Drop Tester

1-rocker arm; 2-sample; 3-hoist; 4-console; 5-sliding table; 6-bracket

(2) Test parameters

The parameters of the vertical impact drop test include drop attitude, number of drops and drop height. The drop posture is divided into three types: face drop, edge drop, and corner drop. For these three drop postures, it is necessary to ensure that the center of gravity of the sample passes through the dropped surface, line, and point. The drop posture of each package and the number of drops of each posture shall be carried out according to relevant professional product standards, product technical conditions or relevant agreements. The drop height should generally be stipulated in the relevant professional product standards, or in accordance with the agreement between the two parties. When there is no professional product standard, you can refer to the relationship between the drop height and the transportation method and quality of the package given in Table 6-2.

Table 6-2 Drop Height of Civil Packaging

Military packaging has higher requirements for drop height than civilian packaging. You can refer to the Chinese military standard "Military Packaging Test Method Free Drop Test", as shown in Table 6-3 for the relationship between the drop height and the quality and size of the package.

Table 6-3 Drop height of military packaging

In the drop test of fuze and ammunition packages, in order to test the safety of packaged products, the selected drop height is higher. In my country's military standard "Conventional Weapons Type Test Method: Ammunition Packaging Test Drop Test", it is stipulated that a 12m vertical impact drop test is required for seaborne ammunition packaging, and a 3m vertical impact drop test is required for other items.

The drop test machine is composed of a drop test bench body and an electrical control box. The main technical parameters are as follows.

①Maximum weight of specimen: 100kg.

②Maximum size of test piece: 1000mm×800mm×1000mm.

③ Drop height: 300~1500mm.

④ Drop method: drop on the surface, edges and corners, as shown in Figure 6-5 (a), (b) and (c).

Figure 6-5 Surface, edge and corner drop

1-corner, edge drop frame; 2-package; 3-tray

(3) Test method

The number of samples in each group is generally not less than 3 pieces. Before the test, each part of the sample should be numbered according to GB4857.1, and a condition should be selected according to GB 4857.2 to adjust the temperature and humidity of the sample. Test according to the national standard GB4857.5 "Package, transport package, vertical impact drop test method". The specific test steps are as follows.

① Lift the sample so that the sample meets the predetermined drop state. For parallelepiped packages, when the surface is dropped, the falling surface of the sample should be parallel to the impact surface, and the maximum included angle should not exceed 2°; when the edge is dropped, the gravity line of the sample should pass through the dropped edge to form the edge. The error of the angle between one of the two planes and the impact surface is not more than ± 5° or 10% of the angle (whichever is greater), so that the edge of the drop is parallel to the horizontal plane, and the maximum angle is not more than 2°, when falling at an angle, make the gravity line of the sample pass through the dropped angle, and the error of the included angle between at least two planes constituting this angle and the impact surface should not be greater than ± 5° or 10% of this included angle ( whichever is greater).

For a cylindrical package, the drop posture includes the drop on the top and bottom surfaces, the drop on lines 12, 34, etc. parallel to the axis of the cylinder, and the drop on points 1, 2, 3, 4, etc. on the edge. In the above three predetermined drop states, the gravity line of the sample must pass through the dropped surface, line, and point.

For packaging bag or bag shape samples, the drop attitude includes the drop of 1 and 3 sides, the drop of 5 and 6 end faces, and the drop of 2 and 4 sides. In the above three predetermined drop states, the gravity line of the sample must pass through the dropped surface, end surface, and side surface respectively.

② Lift the sample to the required drop height position, and the difference between the lifting height and the predetermined height shall not exceed ±2%.

③Release the sample and let it fall freely.

④ After the test, check the damage of the packaging and contents according to the relevant product standards. If necessary, the function test of the contents shall be carried out to check whether the contents are damaged. If there is damage that affects the use of the product, such as product leakage, packaging box falling apart, and damage to the appearance and function of the contents, the package should be judged to be unqualified. If there are only some damages on the packaging that do not affect the performance of the product, such as peeling paint, slight scratches on the surface, loose components and other damages allowed by the product standard, the package can be judged to be qualified.

In the drop impact test of some specific transport packages, an acceleration sensor can be installed on the contents to detect the maximum impact acceleration generated by the contents to determine whether the package is qualified.

When the drop impact test for testing the safety of packaged ammunition needs to be carried out in a special test facility. When the outer packaging has "fatal damage" (such as ammunition explosion), or the inner packaging has more than "serious damage" (such as functional damage to the inner packaging), or when the number of "serious damage" to the outer packaging exceeds the number of samples When more than 1/3, it is determined that the package is unqualified.