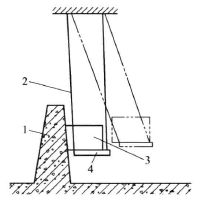

The principle of the pendulum impact test is basically the same as that of the inclined plane impact test, and the selection of test parameters such as impact velocity, test times and test sequence is the same as that of the inclined plane impact test. However, the test equipment used in the pendulum impact test is the pendulum impact test machine, as shown in Figure 6-7, which is mainly composed of a suspension device, a table and a baffle.

Figure 6-7 Pendulum impact testing machine

1—baffle; 2—suspension device; 3—sample; 4—platform

The relationship between the impact velocity of the sample and the lifting height of the platen is:

h=v²/2g

In the formula

h——the lifting height of the platform, m;

v - the impact velocity of the sample, m/s;

Before the test, each part of the sample should be numbered according to GB 4857.1, and a condition should be selected according to GB 4857.2 to adjust the temperature and humidity of the sample. Test according to the national standard GB4857.11 "Packaging and transportation package horizontal impact test method (inclined plane test, pendulum test)". The specific test method is to first place the sample on the platform to ensure that the impact surface (or edge) of the sample just touches the impact surface of the baffle when the platform is in a freely suspended and static state. According to the predetermined impact speed, the platen is lifted to a certain position, and then the platen is released, so that the sample hits the baffle horizontally. The error of the impact velocity shall not be greater than ±5% of the predetermined horizontal impact velocity. After the test, according to the relevant product standards, check the damage of the packaging and contents, and analyze the test results.