GB/T 13217.1 stipulates the test method of ink color and tinting strength. After studying GB/T 13217.1-2020 "Ink Color and Tinting Strength Test Method" in detail, NBCHAO is here to provide users with Do some reading.

The wire rod in the standard mainly refers to the wire-wound wire rod coater based on the Mayer principle, which stipulates that the wire rod: the diameter of the rod body is 9mm, the length is 170mm, the length of the part wrapped with stainless steel wire is 100mm, the diameter of the stainless steel wire is 0.12mm, tightly wound Arranged neatly without gaps. According to the experience of the north and south tides in the past 10 years, in practical applications, more we define the film thickness by the wet film thickness μm. For the ink color and tinting strength, it is often related to the film thickness, substrate and the performance of the ink itself. Preparation accuracy and film thickness are the most basic level of color comparison and color comparison. If you can't make a good color sample, you can't talk about color matching and color comparison.

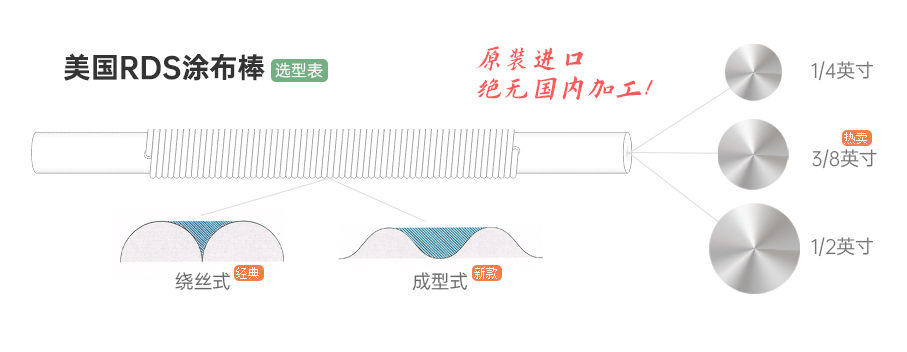

GB/T 13217.1-2020 "Ink Color and Tinting Strength Test Method" stipulates that the wire diameter is 0.12mm. We open the selection table of RDS wire rod in the United States for comparison, and we can find that it is between No. 4 and No. 5 rods. The corresponding wet film thickness is about 9~11.4. Users can choose between these two models. Of course, sometimes customers will scratch the "scratch" phenomenon. On the one hand, this is a problem caused by the quality of the wire rod. On the other hand, we must also pay attention to the fineness of the ink. What about grooves with a size of 9 μm? Users can choose 0~15μm scraper Fineness Meter for measurement.

As for the length stipulated in the standard, the North and South tides think it is unnecessary. As long as the film thickness and width of the wire rod do not exceed the limit of the wire rod itself, taking RDS as an example, a 40cm long film can be prepared with a 30cm wide film. If you want to prepare a 10cm film Left and right, just drop the ink evenly on the 10cm width of the test plate and scrape the sample.

Another question: is it possible to use squeeze instead? In fact, it is possible. The manufacturing process of the two is different, and the actual principle is the same. It is only because of the process problem that the groove formed between the wire rod and the steel wire is a V-shaped groove, while the extrusion type is a U-shaped groove. The latter consumes more ink in theory. In fact, there is a problem with the transfer amount of the machine. If it is to calculate the coating amount of the upper ink, the wire rod is more accurate, and the extruded wire rod needs to deduct the transfer amount (generally 75~ 80%). In addition, the broken wire of the wire rod is basically a marketing threat, and everyone will not have these questions after using it.

Finally, the steel wire rods made by current domestic manufacturers cannot be made very thin, and there is indeed a gap with foreign ones in terms of error, craftsmanship and service life. The extruded wire rods of about 10 μm are the current internal inspection results of the North and South Tide. Looking at it, the error is still not small, and I also hope that domestic manufacturers can become more and more sophisticated in ultra-thin coatings.