(1) Purpose and Definition

The thickness of the ink (Fineness) is also a very important quality indicator, because it is not only related to the application performance, but also related to the rheological properties and economic benefits of the ink.

If the ink is too thick, it will cause a lot of printing failures, for example, in lithographic printing, it will cause plate destruction and ink accumulation (plate stacking, blanket stacking, paste plate) and so on. Solvent-based inks can cause plate damage, and the ink itself is prone to precipitation and so on. Generally speaking, when printing a printed matter with a relatively thin screen line, the fineness of the ink is required to be higher.

If the dispersion of the oil is unsatisfactory, generally speaking, its performance is also unsatisfactory. When people look at the bunching, it will feel not smooth, smooth, soft and "chunky". Its rheological properties are also unsatisfactory, which greatly reduces its printing performance.

Due to poor dispersion, the strength of the pigment cannot be fully exerted, which affects the value of the pool ink itself.

The thickness of the so-called ink refers to the degree to which solid powdery substances such as pigments and fillers mixed in the binder are dispersed.

There are many methods for measuring ink thickness, such as microscope method, dilution precipitation method, centrifugation method, etc., but because these methods are relatively complicated to operate and take a long time, they are generally only suitable for research work.

(2) Determination method of thickness

What we introduce here are two relatively simple and common methods, one is called the glass plate method (or thin ink film method), and the other is called the scraper Fineness Meter (scraper meter, fineness board—Grind Gage )Law. Of course, the former cannot be expressed numerically.

1. Glass plate method.

(1) Equipment and materials.

① Minor ink knife.

② scraping (ink) knife.

③Glass plate (the size can be determined according to the needs).

(2) method. Take a small amount of standard sample oil with a small ink knife and place it on the left side of the glass plate, and take a small amount of sample ink and place it on the right side of the glass plate. The positions of the two should be adjacent and not connected.

Use force to scrape the two inks on the glass plate into a thin layer from top to bottom with the scraper. Then use experience to judge the thickness of the standard sample and sample with eyes.

(3) Precautions.

① When scraping, the strength should be uniform and the speed should be fast to prevent inconsistent thickness. The thickness of the ink layer is different, and the conclusion of different fineness may be drawn. Therefore, repeated practice and rich experience are required.

② Observe and judge immediately after the ink layer is scraped. Observation can be carried out under different light and different angles. Generally speaking, the surface of the ink layer that is thick and poorly dispersed is relatively rough and has no light release, and the surface of the ink layer that is fine and dispersed is relatively smooth and bright.

刮(墨)刀的刀口(即刀刃)与玻璃板均需绝对平滑,而且是全面平滑,否则刮成的薄层油墨就会厚薄不一致,造成判断上的困难。

2.刮板细度计法。

(1)器具与材料。

①器具;

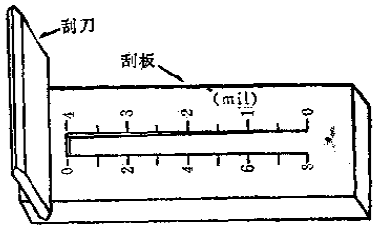

1、刮版细度计(俗称刮板仪)。

2、0.1毫升吸墨管。

3、注射器(每刻度0.1毫升)或滴定管

4、小调墨刀。

5、玻璃板。

②材料:6号调墨油(事先经滤纸过滤)。

(2)方法。用吸墨管吸取一定量的油基(例如0.3毫升),置于玻璃板上,然后用注射器加入6号油(加入量需视油墨的流动度而定,流动度在7毫米以下者,可加入5倍的6号油,27-32亳米之间的可加入4倍的6号油,32毫米以上者可加入3倍的6号油,当油墨的流动度大于45毫米以上时可不必加入6号油)。用小调墨刀充分调合均匀。

用小调墨刀取一些调合均勾的油墨置于刮板仪的凹槽深处。然后以双手的姆指和食指握住刮刀,垂直横置于刮板仪上凹槽深处的油墨上,在保持刮刀垂直的情况下将刮刀由上往下刮至刮板仪的最浅处,使油墨充满刮板仪的凹槽。

刮好后立即将刮板表面以30度角斜对光源,观察颗粒密集点的位置,According to密集点的位置来确定试验油墨的细度。

(3)注意事项

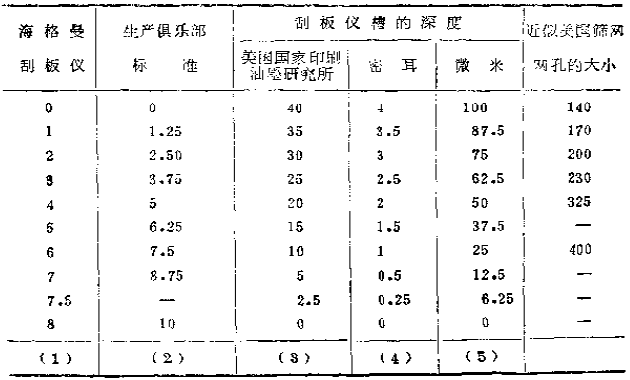

①刮板仪一般有单槽式(如图所示)和双槽式两种。其刻度一般有25微米、50微米和100微米三种。我国油墨行业目前普遍采用50微米的。

国际上采用双槽式25微米刻度的比较多。

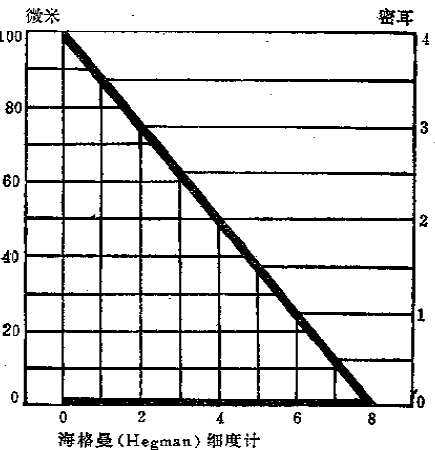

欧洲使用的海格曼细度计的刻度与微米和密耳的换算关系可见图27-5。可以看出,在数字上海格曼与它们是成反比关系的。

②我国目前都米用加油稀释法来测定油墨的细度。国际上有的国家则采用油墨直接测定(即油墨中不加钰何稀释的油类〉。这样,在刮墨时,油墨中的粗颗粒就会被刮刀刮成条状刮痕,有入曾According to这些刮痕的位置和多少,提出过许多不同的读数方法。其中之一是:先读出四条粗粒刮痕的起点读数和十条刮痕的起点读数,二者读数愈高表示油墨粒子愈粗;二者之差愈大,则最大粒子的范用愈广。

③The ink needs to be blended evenly when it is diluted with oil, but not too much force, so as not to produce grinding effect and make the result inaccurate. At the same time, care should be taken to prevent dust from falling.

④ When holding the scraper with both hands horizontally on the scraper, do not use too much force, but also avoid being too light. Not to mention one side.

⑤ Regarding the calculation of fineness, the current habit in our country is to observe the value of densely packed particles. That is, when there are more than 15 particles in a scale range, it is counted as the value on the scale, and if there are no more than 15 particles in this scale range, it is counted as the value on the lower scale.

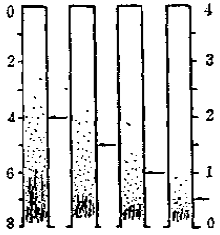

The calculation and judgment of the concentration point of fineness can be seen in the figure. The arrow in the figure refers to the concentration point scale number of fineness. The scratches of coarse particles can also be seen from the figure. The coarser the particles, the more the scratches appear on the top.

⑥The various tools used to measure the thickness should be wiped with a clean soft cloth or cotton yarn. Especially the scraper and scraper should not be scratched or damaged.