(1) Purpose and Definition

The drying (drying ) of the ink is a very important indicator. It is impossible to imagine the consequences of an ink printed on the substrate that dries slowly or even does not dry.

If an ink does not dry satisfactorily, it is not a good quality product. We know that many failures in the printing process are caused by poor ink drying. For example, sticky prints (smearing on the back) are caused by poor ink drying. Therefore, almost all ink makers in the world are struggling for it.

(2) Determination of dryness (dryness)

Since there are many drying forms of inks, the methods of determination are also different. For example, UV drying inks need to be irradiated with ultraviolet rays, while thermosetting inks need to be heated and so on. Since there are many methods for measuring ink dryness, the degree of standardization is poor. Here are several more common methods, which can be selected according to needs.

dry method.

Generally, inks that are mainly dried by oxidative conjunctiva can be determined by this method. However, because the ink is scraped (or printed) on the paper for measurement, the influence of osmotic drying on the drying time cannot actually be ruled out.

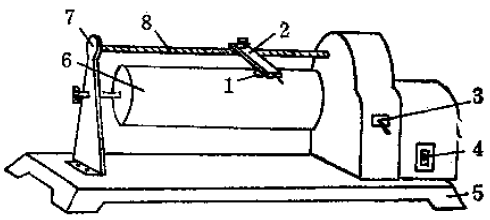

There are many types and models of dryness meters, but their purposes and effects are similar. Most of the dryness meters used in my country are drum-type dryness meters, as shown in Figure 27-10. In the figure: 1. Round pressure wheel, 2. Gravity weight; 3. Speed regulator: 4. Switch; 5. Base: 6. Metal roller; 7. Bracket; 8. Screw.

(1) Equipment and materials.

①Apparatus.

( i) Rolling-type dryness Tester.

(ii ) Balances with one-thousandth accuracy.

(iii) Minor Ink Knife.

(iv) scraping (ink) knife.

(v) Two glass plates of equal weight.

② material.

( i) Drying oil (one can be fixed arbitrarily).

(ii) Writing paper (approximately 32 x 8 cm).

(iii) Sulfuric acid paper.

(2) method. Use a balance with a precision of one-thousandth to weigh the sample ink and dry oil in a specified proportion on the glass slide, and mix them fully and evenly. Weigh the standard sample ink and dry oil in the same way, and fully mix them evenly.

Put a small amount of the standard ink and sample ink with drying oil on one end of the writing paper side by side, scrape a scraping sample about 30 cm long with a sharp ink knife (do not leave a thick ink layer), and record the scraping time.

Stick one end of the scraping sample on the sulfuric acid paper (the ink faces the sulfuric acid paper), then wrap the scraping sampled sulfuric acid paper on the metal cylinder 6, so that the scraping sample is clamped between the metal roll and the sulfuric acid paper (long The scraping sample of the strip should be parallel to the roller), and the paper is clamped with a strip.

Move the round pressing wheel equipped with a 100 g weight to the left end of the screw and press it on the metal roller wrapped with sulfuric acid paper. Estimate the drying time of the tested ink and select the appropriate drum speed (adjustable speed regulator), generally so that the circular pressure wheel can go the entire distance from left to right and the oil can dry. Then turn on the switch and record the time at the same time. At this time, the roller starts to rotate, and the circular pressure wheel also starts to move from left to right, which is equivalent to timing marking.

After the round pressure wheel has traveled the full distance from left to right or the specified time, remove the sulfuric acid paper and check the number of ink marks on the sulfuric acid paper, and then convert it into time. Add this period of time to the time after the scraping sample is scraped and the instrument starts to rotate, which is the drying time of the tested ink.

(3) Precautions.

①Whether the thickness of the ink sample is uniform or not will affect the drying time. A thick ink layer will dry slowly, and vice versa, it will dry quickly.

② Judgment of drying time: At the beginning, there is more transfer printing ink on the sulfuric acid paper. As the ink dries, the ink transferred to the sulfuric acid paper becomes less and less (the color becomes lighter and lighter), so that the sulfuric acid paper is completely dry. No more ink on paper.

③Approximate amount of dry oil added: if it is white dry oil, it can be added between 5 and 10%.