Filter paper staining method (press scraping method). The dried ink scraping sample (or printing sample) is in contact with the filter paper permeated with selected acid, alkali and other liquids, and after a certain period of time under a certain pressure, observe the change of the ink scraping sample (or printing sample) And the dyeing degree of the filter paper, and then evaluate the resistance performance according to the specified rating method.

(1) Equipment and materials.

①Apparatus.

(i) Minor Ink Knife.

(ii) scraping (ink) knife.

(iii) Two glass plates (9×12 cm). iv) One kilogram weight.

(v) 100ml steaming nozzle. (vi) Small tweezers.

(vii) Desiccator (or corresponding airtight container).

② material.

( i) Scratch paper.

(ii) Qualitative filter paper.

(iii) Selected acid, alkali and other solutions.

(2) method.

Scratch a sample according to the determination of color, but do not leave a part of the thick ink layer, and let it dry at room temperature.

Take a small glass plate and put it in a desiccator (or other airtight container) placed horizontally. The bottom of the desiccator (or other container) should be filled with some clean water beforehand to keep the humidity inside. Cut half of the ink squeegee and place it on a small glass plate with the ink layer facing up.

Inject the selected acid, alkali and other solutions into a 100ml evaporating dish, take 10 pieces of qualitative filter paper, clamp them with tweezers, and immerse them in the solution to make them completely soaked. The saturated filter paper was then overlaid on the ink scrape.

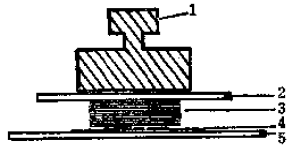

Press a small glass plate on the filter paper, press a one-kilogram weight on the glass plate (see picture), and then seal the desiccator (or other container). After 24 hours, open the container, remove the weight and the small glass plate above, take out the filter paper and ink sample, dry the filter paper at room temperature, and then check the number of stained sheets of filter paper. The first filter paper that comes into contact with the ink squeegee is not counted when counting.

Schematic diagram of filter paper staining method

Rinse the ink scraping sample with distilled water until neutral (referring to the determination of acid and alkali), dry it at room temperature , and check the change degree of the ink scraping sample (compared with the original scraping sample that has not been measured).

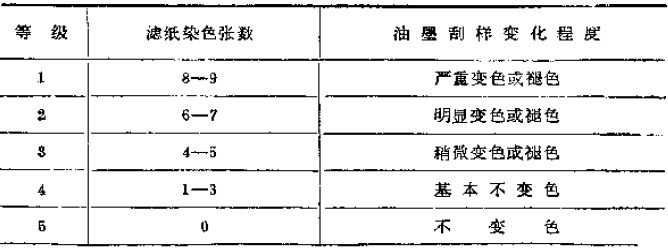

According to the number of dyed sheets of filter paper and the degree of change in scraping samples, the grades are rated according to the regulations listed in the table.

(3) Precautions

① The drying degree of the ink scraping sample has an impact on the test results. A scratch-off sample that is not dry may have the disadvantage of floating the ink after being soaked in liquid.

According to the International Standard Organization ISO2834, the method drafted by the "Printing Process" Technical Committee ISO/TC130, the test should be carried out with a printed sample. The printed sample should be placed in the air for 72 hours (24 hours or more for solvent-based inks) to dry it. Paper used for proofs should be neutral, free of photobleach, and free of mechanical wood pulp.

②Among the grades, grade 5 is the best and grade 1 is the worst. When rating, if the number of dyed sheets of filter paper does not coincide with the change degree of the ink scraping sample, use the worse of the two for rating.

③ The change of scratch paper should also be considered, which can be verified by doing a blank test.

④ The temperature during measurement can generally be between 20-35°C.

⑤The concentration of detergent solution is generally 1% (5% is also useful in Europe).

⑥ When measuring the soap resistance of ink, 1% soap solution can be used.

Another way to measure the soap resistance of inks is to stick the scraping sample on a flat (scrape it in advance if the soap is not dirty), and then put it into a closed container with clear water at the bottom (put a piece of soap inside). glass, place the soap with the scraper on the glass, with the scraper under the soap). After 24 hours, take out the scraping sample pressed under the soap, rinse it with distilled water to neutrality, and after drying at room temperature, observe the staining degree of the soap and the change degree of the oily scraping sample. Then grade according to the regulations listed in Table 27-3 (colorless soap should be used for this measurement to facilitate observation and judgment).