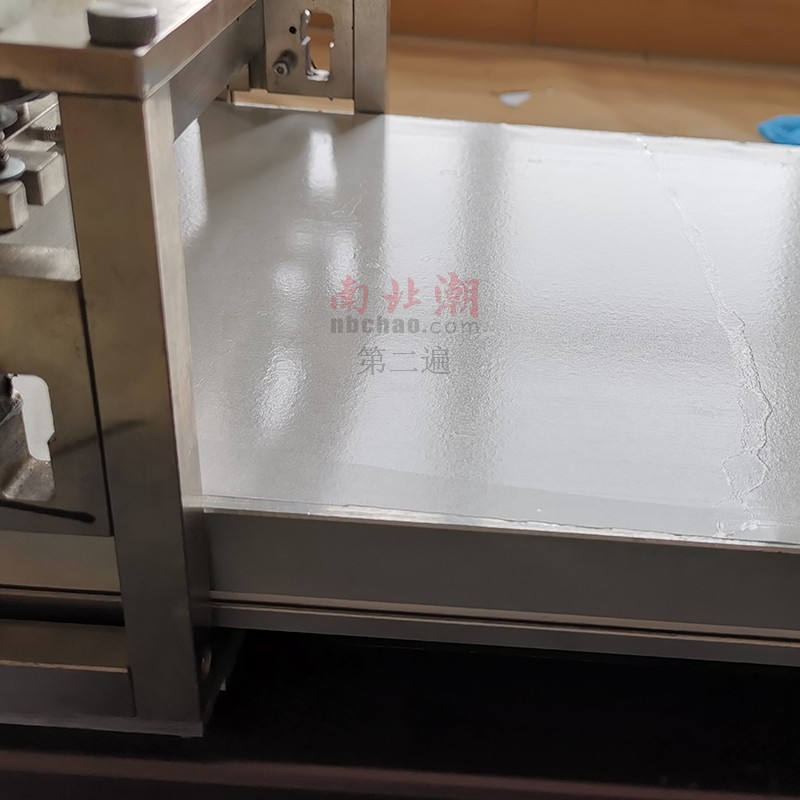

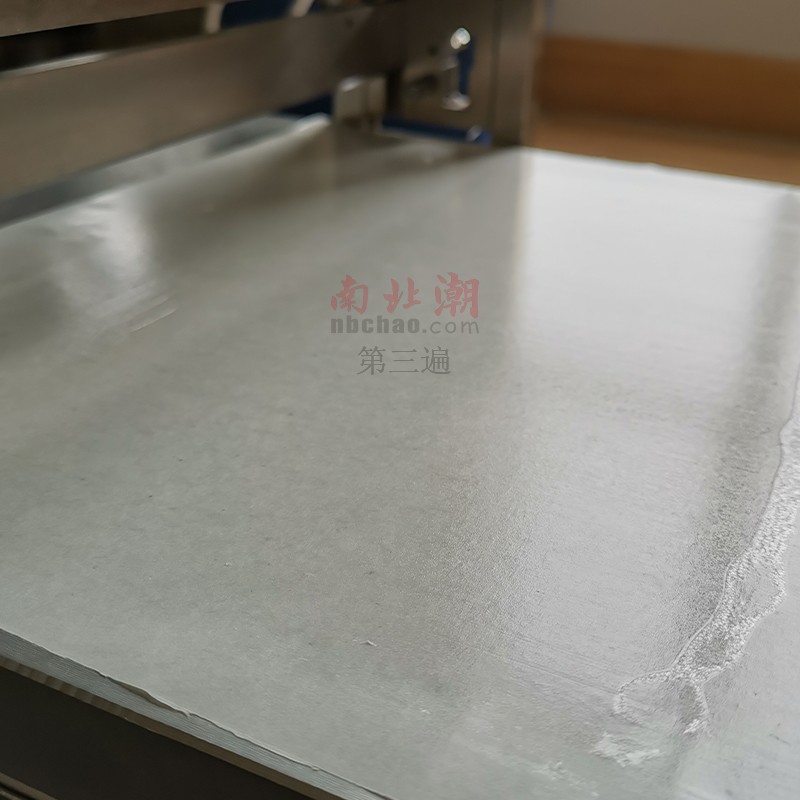

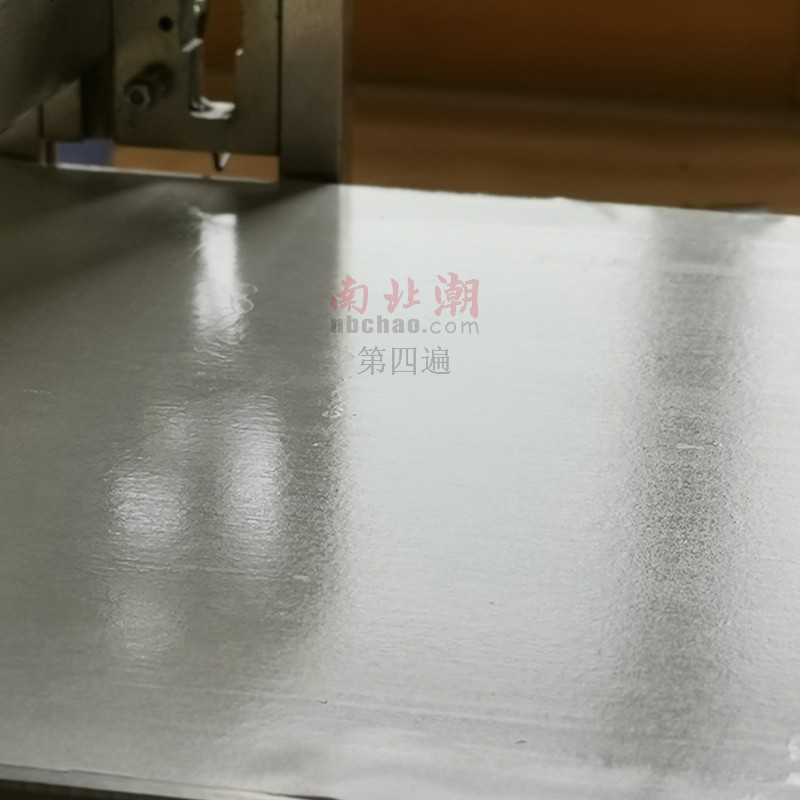

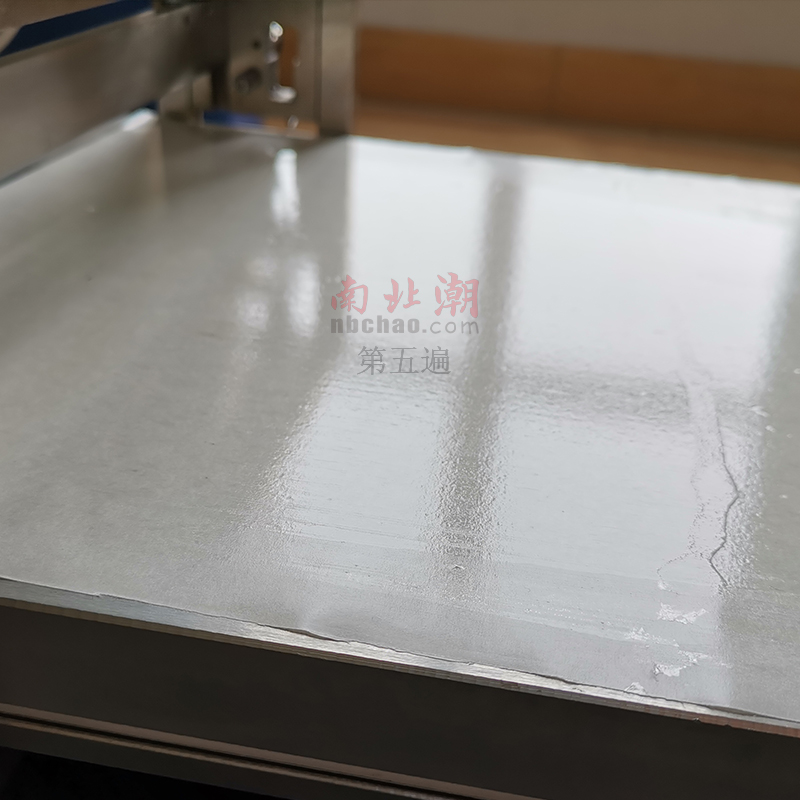

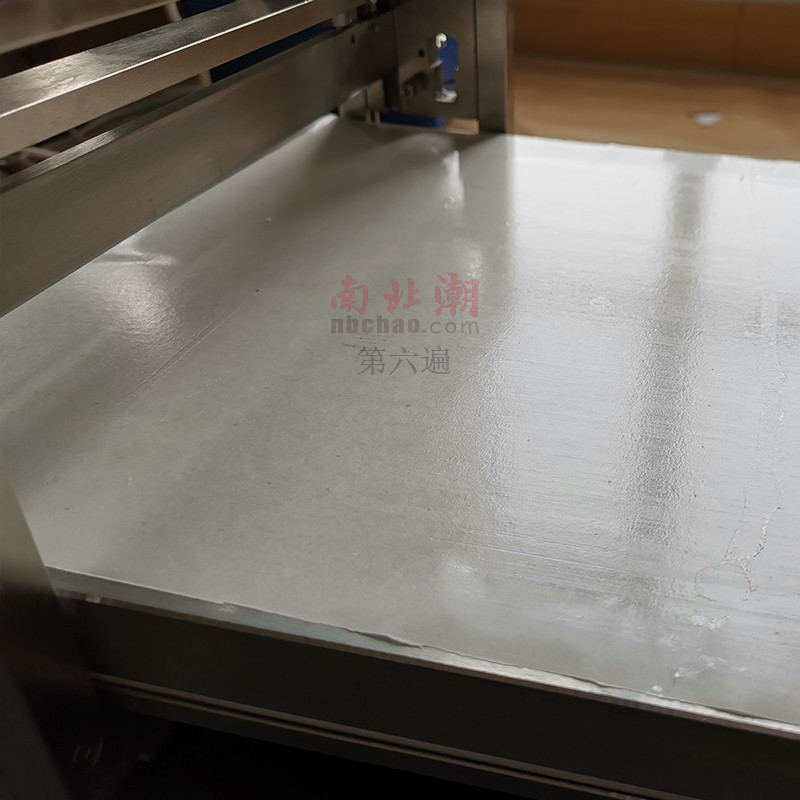

For any material, the Testers always mess up when making multi-layer films. The big reason is not the material problem, but the substrate material, flatness, wire rod accuracy, and manual control errors when preparing the coating film. . In this issue, the North and South Tide uses a wire rod vacuum adsorption film coating machine to prepare multi-layer polymer films. Let's take a look at the effect.

The coating film seems to be easy to operate, but it actually has a lot to do with the technicians. In addition to the manual control error and the flatness of the substrate that everyone will think of, there is also a little trick. The width and length of the scraped film should be greater than that of the second layer, and so on, the final layer prepared is the film you want. In addition, the speed of scraping the film with high viscosity is slower, and that of low viscosity is faster. At the same time, when preparing a multi-layer film, you must wait for the next layer of film to dry, otherwise there may be unexpected problems. All multi-layer coatings have high requirements on manual speed, pressure and flatness. As long as one layer is not prepared well, the subsequent ones will be scrapped. So it will be a good choice to use a film coating machine in this regard. NBCHAO provides sample testing service, and interested friends can contact the customer service of the mall.