The automatic film coating machine is used by more and more industries through constant pressure, constant speed and vacuum adsorption functions. For some films, vacuum adsorption function is required. For some hot melt adhesives, it is necessary to use to the heating function on the coater.

When experimenting with film coating, using a Film Applicator can also avoid human-made coating errors. For the Film Applicator itself, the film thickness is determined by the wire bar or preparer on the Film Applicator. The effect of the coating film is determined by many factors, such as the material of the substrate, the material itself, etc. This article brings some coating cases of customer proofing, and you can see the coating effect of the automatic coating machine.

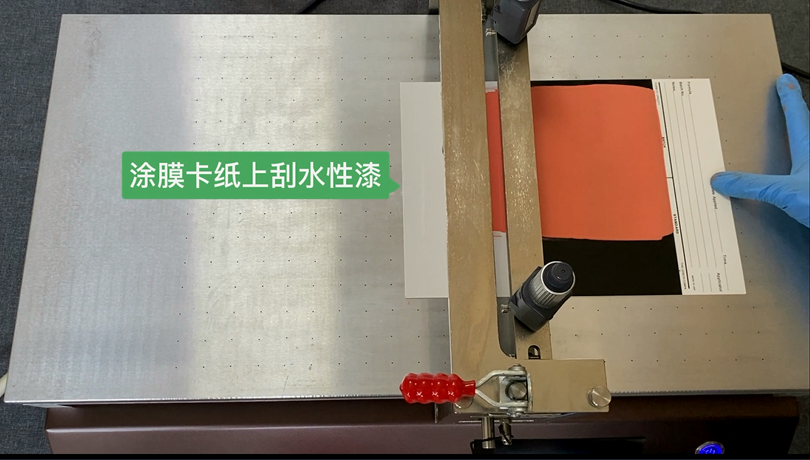

Scratch-off paint on coated cardboard

Squeegee thick glue on tinplate

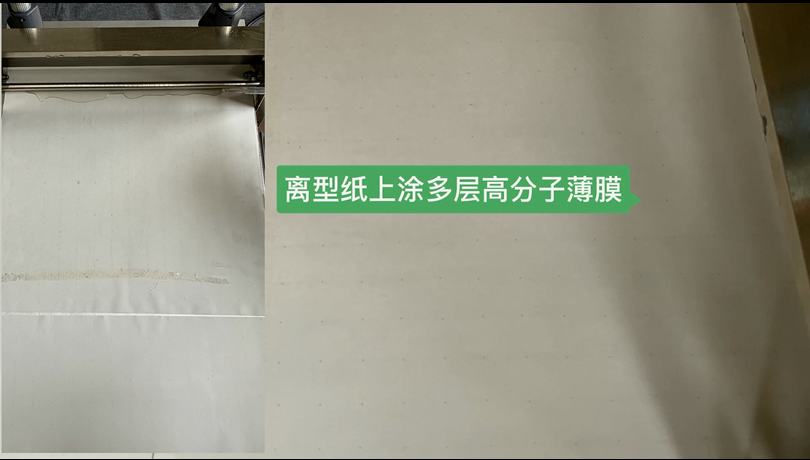

Coated multi-layer polymer film on the release paper

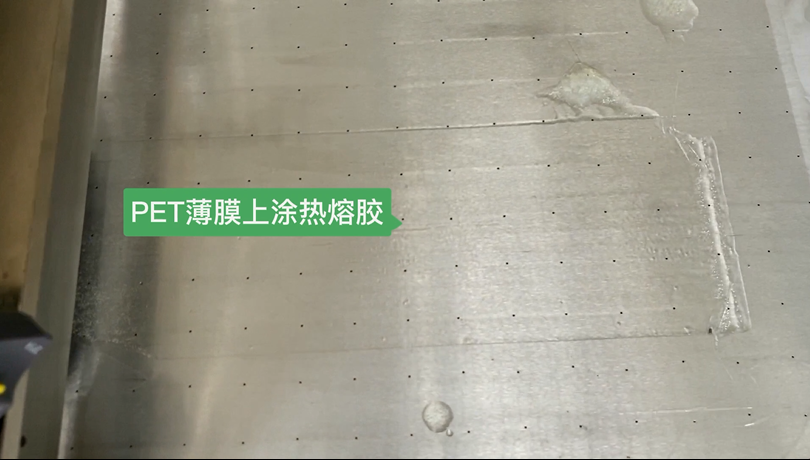

Coating hot melt adhesive on PET film

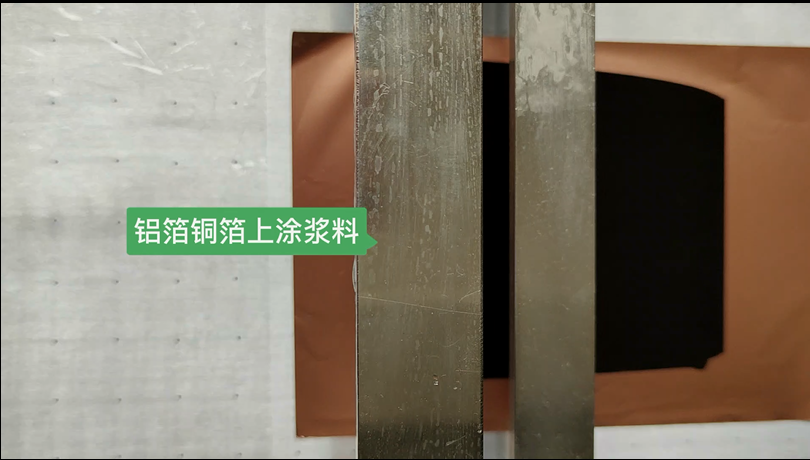

Coating slurry on aluminum foil and copper foil