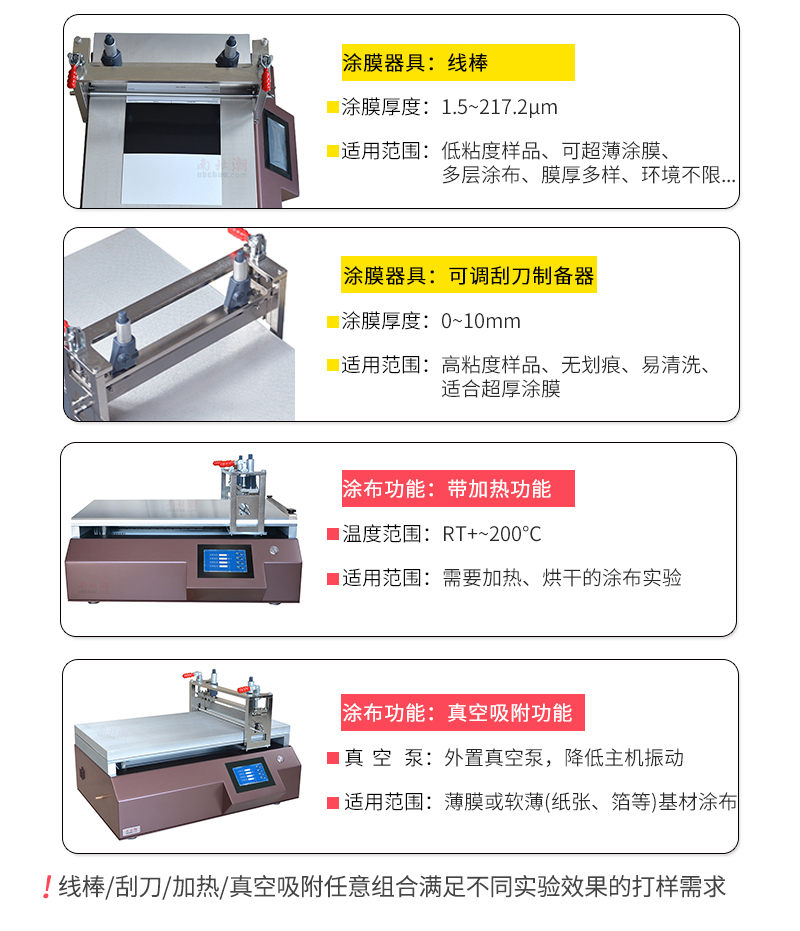

The experimental small film coating machine can cooperate with wire rods, Wet Film Applicators, and scrapers for automatic coating proofing, and automatically scrape the film through the machine to reduce the error of manual proofing and improve the repeatability and speed of the coating film. Because the requirements of coating film proofing are different and the required functions are different, such as maintaining a constant temperature and heating, etc., different experimental coating opportunities are different, and special functional designs can be made according to different needs.

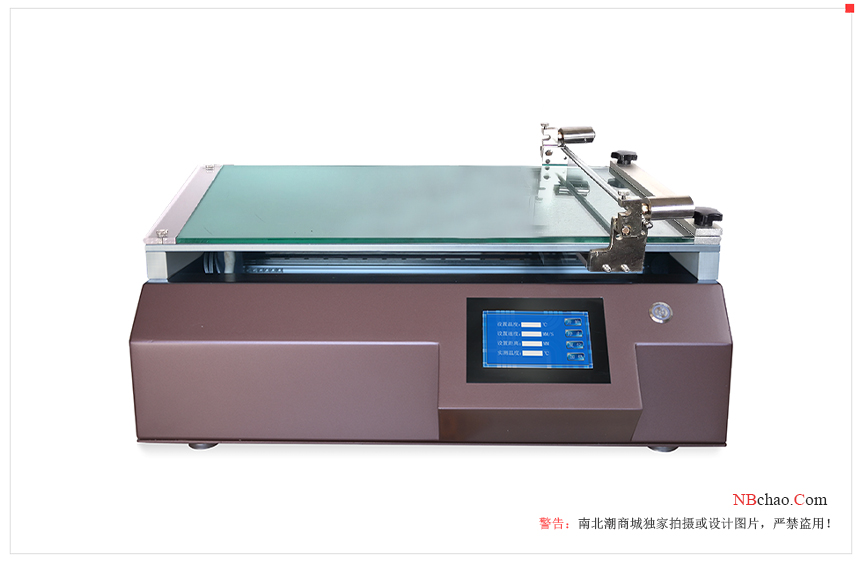

The general automatic film coating machine is coated by a coating machine equipped with a wire rod and a scraper. The coated bottom plate is made of glass or aluminum plate, and the coating speed can be directly adjusted. Coating thickness is controlled by wire rod and drawdown blade. When the coated sample needs to be heated to coat, or when the normal temperature will affect the normal coating effect, such as hot melt adhesive, it is necessary to use the heating effect, and the heating temperature of the NBCHAO film coating machine can reach 0~200℃.

In the coating process, in addition to the sample to be coated, the substrate on which the coating is applied is also very important. The vacuum adsorption coating machine is converted into a vacuum adsorption plate on the basis of the coating machine. For some soft and curved substrates In order to ensure the flatness of the substrate, to improve the effect of the coating film, especially some materials such as thin films.