This article is an excerpt from Ding Zewen of Beijing University of Chemical Technology's paper "Preparation and Electrochemical Properties of Conductive Polymer Coated Carbon-Sulphur Composite Cathode Materials"

(1) Grind the prepared sulfur-based cathode material, conductive carbon acetylene black, and polyvinylidene fluoride in an agate mortar for a certain period of time at a mass ratio of 7:2:1, and then add N- For methylpyrrolidone NMP, follow the principle of a small amount and multiple times, and continue to grind during the dropwise addition until it becomes slightly viscous, and then grind again for about 30 min.

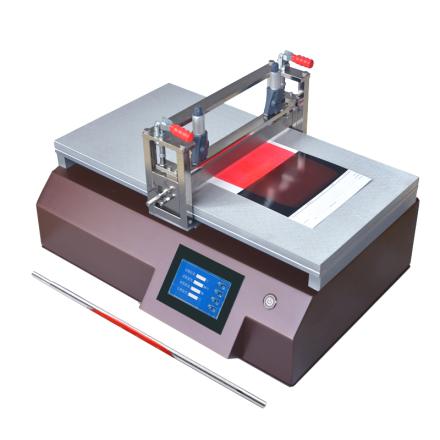

The ground sample was evenly coated on the aluminum foil with a scraper and a coating device , and the coated aluminum foil was dried in a vacuum oven for 12 hours at a temperature of 60°C. The dried smears were cut into circular positive electrode sheets of lithium batteries with a diameter of 14 mm by a tablet machine, and put into a vacuum glove box for battery assembly.

(2) The CR2032 button lithium battery was assembled in an argon atmosphere glove box. The electrolyte solution used for battery assembly was 1:1 ethylene glycol dimethyl ether (DME) and 1,3-epoxypentane (DOL) and a concentration of 1 M lithium bistrifluoromethanesulfonylimide ( LiTFSI) solution, and added 1 wt% lithium nitrate (LiNO3). The diaphragm used is the 2400 series organic diaphragm of Celgard Company of the United States.

(3) When assembling, first drop an appropriate amount of positive electrode electrolyte into the negative electrode shell with a pipette, and then load the circular lithium metal, organic diaphragm, 14 mm circular positive electrode piece, spring piece and lithium battery positive electrode shell in a certain order, and During this loading process, an appropriate amount of electrolyte is added. Finally, the assembled battery is pressed with a tablet press.