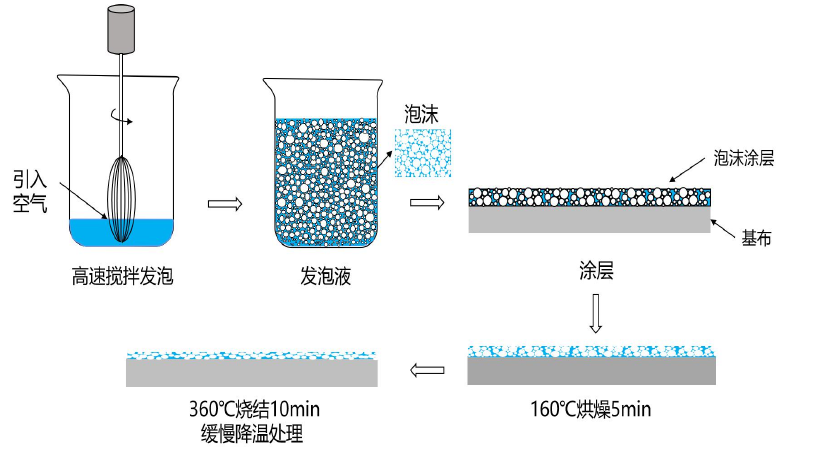

According to the above-mentioned research content, the selected experimental reagents and formula, the optimized suitable foaming and stirring method, obtain the method for preparing PTFE foaming solution. According to the research on drying and sintering process parameters in Chapter 4, the appropriate temperature and time of heat treatment were confirmed , and the specific process route for preparing PTFE foam -coated glass fiber composite filter material was obtained, as shown in Figure 5-1 .

Figure 5-1 Preparation route of PTFE foam coated glass fiber composite filter material

Preparation method of PTFE foam coating glass fiber composite filter material

(1) Use a pipette to take PTFE emulsion, 1g of betaine, 2g of Tween 80, 3g of acrylic resin, and 1g of methylcellulose, and add them to a 1000mL plastic measuring cup according to the specified order;

(2) Turn on the blender, install a multi-dimensional stirring rod, adjust to a high-speed gear (5000r/min), put the blender into the prepared solution to stir at a high speed, and foam rapidly to obtain a foaming solution.

(3) Open the film coating machine, pipette a certain amount of prepared PTFE foaming liquid, start coating, the scraper is pushed forward at a constant speed, and the foam is coated on the glass fiber woven fabric under the action of the scraper;

(4) Put the glass fiber woven fabric that has just finished coating into the hot air dryer , set the drying time to be 5min, and the drying temperature is 160°C;

(5) take out immediately after drying is finished, transfer to the electric blast oven of high temperature rapidly and carry out sintering, and sintering time is 10min, and sintering temperature is 360 ℃;

(6) After the sintering is completed, turn off the heating button of the oven, so that the oven is in a state of slowly cooling down, and continue to slowly cool down the glass fiber woven fabric of the foam coating for 5 hours;

(7) Wait until the temperature in the oven drops to 100°C, take out the processed coated glass fiber woven cloth, cool to room temperature, and obtain the PTFE foam coated glass fiber composite filter material.