The electrode sheet of the half-cell we tested is mainly composed of four parts: active material, conductive agent (acetylene black), binder (PVDF) and current collector (generally aluminum foil for positive electrode and copper foil for negative electrode). The production of electrode sheets mainly includes four steps: pulping, coating, sheet making and weighing calculation.

(1) pulping: after weighing the prepared sample powder as an active material with PVDF and acetylene black according to a certain mass ratio , put it in a mortar, add an appropriate amount of 1-methyl-2-pyrrolidone (NMP), and carry out grind. Mill for thirty minutes to obtain a well-mixed slurry. The solvothermal product is LiFePO4 by mass ratio: acetylene black: PVDF=8:1:1 Accurately weigh the above three substances with a total mass of 0.1 g, then put lithium ferrous phosphate and acetylene black into the mortar and add 300 Microliter of 1-methyl-2-pyrrolidone (NMP), vigorously grind for 20 minutes, then add PVDF, and continue grinding for 10 minutes to obtain a uniformly mixed slurry.

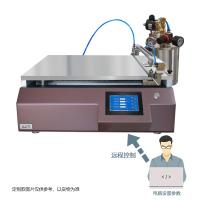

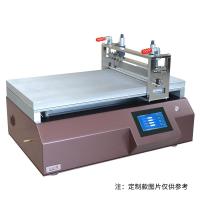

(2) Coating: first, the surface of an aluminum foil of a certain size is cleaned three times with absolute ethanol to remove the oxide layer and residual impurities on the surface, and then dried at a constant temperature of 60°C. Adjust the scale of the scraper, and then use the film coating machine to evenly on the rough surface of the dried aluminum foil, and place the coated aluminum foil at 120 °C for 12 h in vacuum.

(3) Tablet production: first wrap the dry aluminum foil with clean weighing paper, slice make a positive electrode sheet with a diameter of 14 mm, and then place it on the tablet press for pressing sheet, the pressure is 20 MPa.

(4) Weighing and calculation: accurately weigh the prepared electrode sheet and the aluminum foil quality of the same size, obtain the difference M and record it as the quality of the electrode material, and then obtain the ratio of removing NMP from the slurry occupied by the active material to obtain each A polar piece. The content of the active substance on it, and record it. Then put the recorded electrode sheet into the glove box to prevent the active material from being oxidized by moisture.