Taking several representative gravure printing water-based inks as sample inks, through the determination of their basic properties and comprehensive investigation of printing adaptability, combined with the characteristics of this laboratory, a unified test method suitable for plastic gravure water-based inks has been formulated and performance indicators.

ink preparation

According to the set ink formula, add the corresponding emulsion binder into the beaker. After adjusting the speed to a certain value, add wetting agent, leveling agent, adhesion promoter, wax emulsion and other additives in sequence under the action of magnetic stirring. Increase the rotation speed and continue to stir and disperse for about 30 minutes. Finally, slowly and evenly add the color paste to the mixed emulsion, continue stirring and mixing for 30-60 minutes, then add the defoamer, disperse evenly, and filter to obtain the water-based ink.

Ink film preparation

Preparation of ink film by coating bar coating method: cut a plastic film of about 20 cm, spread it on a resin board (or a soft and flat object), take an appropriate amount of ink on the top of the film, and use a coating bar to uniformly force and speed The ink is scraped off to form an ink film. After drying the ink film at room temperature, put it in an oven at 50°C for 10 minutes, and test various properties after 48 hours at room temperature.

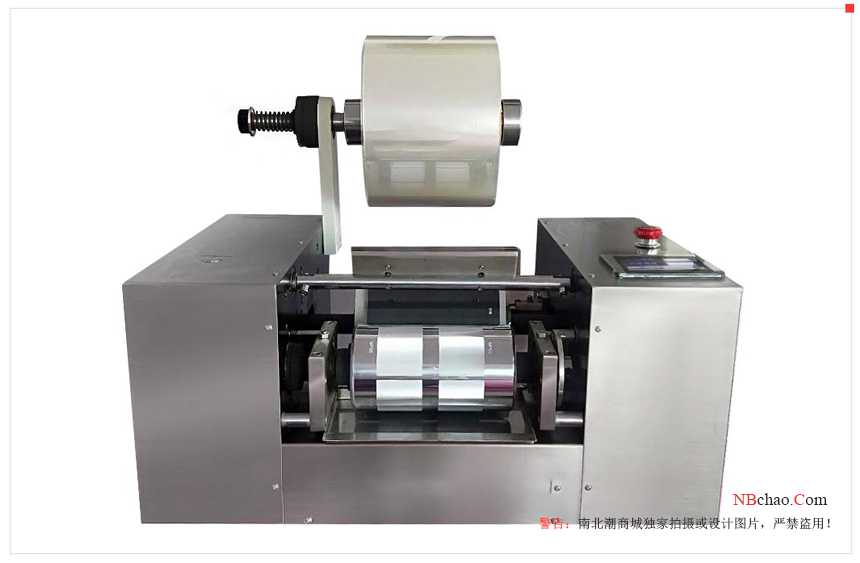

Preparation of ink film by proofing machine proofing method: cut a plastic film of about 20cm×15cm, fix it on the printing rubber wheel of the gravure proofing machine, and evenly drop the ink to be tested on the top of the printing plate, and the length is consistent with the width of the printing plate. Then set the proofing speed to 40m/min, press the "proofing" key to proofing.