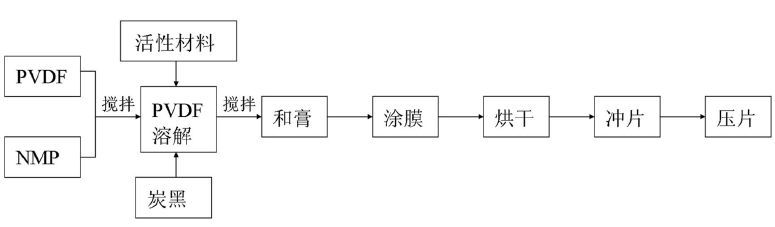

The electrode preparation process is shown in the figure, and there are mainly the following steps:

(1) Paste: add 80 wt% active material, 10 wt% conductive carbon black and 10 wt% polyvinylidene fluoride PVDF) to 1-methyl-2-pyrrolidone (NMP) dispersant in sequence Stir at room temperature for about 5 hours until the slurry is evenly mixed to form a slurry, and then sealed and stored for later use.

(2) Film coating: The film coating process is to evenly coat the above-mentioned reconciled slurry on the copper foil. Specifically, turn on the film coating machine, gently wipe the surface of the film coating machine with a cotton ball dipped in alcohol, then cut out a copper piece of moderate size with a knife, and place the copper piece with the rough side facing up on the film coating machine. On the machine, just cover the vent holes on the surface , then pour the slurry evenly under the four-sided preparer, turn on the vacuum button, and start film coating.

(3) Baking electrodes: Put the uniformly coated copper foil into a vacuum oven at 80 °C and dry overnight.

(4) Tablet pressing: Use a pole piece punching machine to punch into a disc with a diameter of 13.8 mm, then press the electrode piece on the tablet press machine with a pressure of about 60 Mpa to form a flat electrode piece, and finally choose a complete Weigh and record the mass of the electrode sheet with uniform distribution of electrode material.