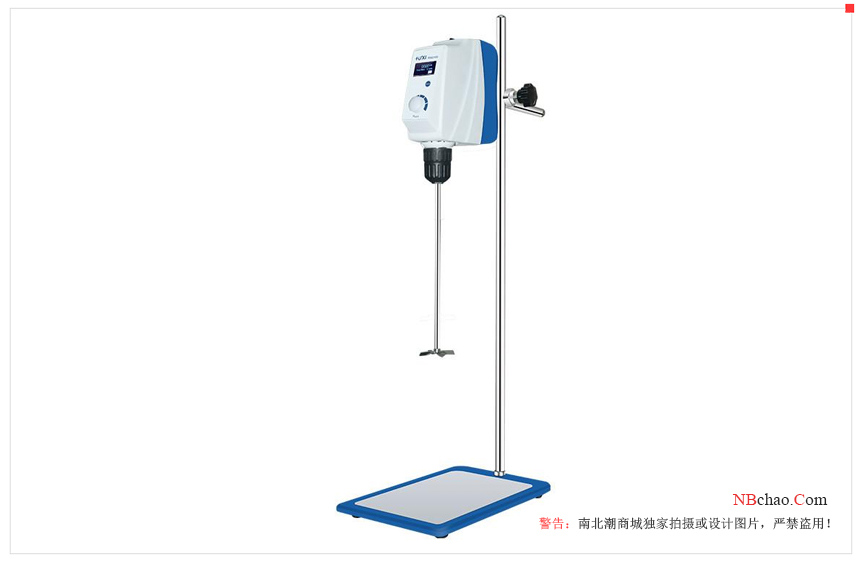

As the basic equipment of the laboratory, the overhead stirrer is suitable for the mixing and emulsification of liquid/liquid, dispersion and slurry of liquid/solid powder in biology, physics and chemistry, cosmetics, health care products, food and so on. But do you know how to choose an overhead mixer? Let the editor tell you in detail below, let's take a look together.

The overhead stirrer is designed for applications such as schools, laboratories and factories to stir viscous substances.

When choosing a mixing version, you need to pay attention to the selection according to the following requirements

1. Select the type of agitator according to the process conditions, mixing purpose and requirements. When choosing the type of agitator, you should fully grasp the dynamic characteristics of the agitator and the causal relationship between the flow state of the agitator during the agitation process and various agitation purposes.

2. According to the determined agitator type and the flow state generated by the agitator during the agitation process, the control requirements of the process for agitation and mixing time, sedimentation velocity, and dispersion, determine the motor power and agitation through experimental means and computer simulation design. speed, stirrer diameter.

3. According to the motor power, stirring speed and process conditions, select the reducer model from the reducer selection table. If the reducer is selected according to the actual working torque, the actual working torque should be less than the allowable torque of the reducer.

4. According to the output shaft head d of the reducer and the support mode of the stirring shaft system, select the frame and coupling of the same model and specification as d

5. Select the shaft seal type according to the do size of the stirring shaft head of the rack, the installation accommodation space, the working pressure and the working temperature

6. According to the installation form and structure requirements, design and select the structure type of the stirring shaft, and check its strength and rigidity. If it is designed according to the rigid shaft, n/nk≤0.7 if the strength condition is satisfied; if it is designed according to the flexible shaft, n/nk>=1.3 if the strength condition is satisfied

7. Choose to install the bottom cover, flange base or flange flange according to the nominal center size DN of the frame, the shaft type and pressure level of the stirring shaft

8. According to the support and anti-vibration conditions, determine whether to configure auxiliary supports.

Choose according to the above conditions, I believe you will be able to choose a suitable overhead mixer to add luster to your work.