At present, the photosensitive electrode paste is mainly used for the production of address electrodes and bus electrodes of plasma display (PDP). Among them, the most stringent requirements are for the production of bus electrodes, and the precision is required to reach 30 μm. The method of making electrodes with photosensitive electrode paste was born in the 1980s. It was invented by DuPont in the United States. In the early days of the birth of photosensitive electrode paste, fine lines with a line width of 60 μm could be produced, which established its foundation from the very beginning. Compared with traditional electronic pastes, photosensitive electrode pastes have the advantages of fast curing, less pollution, and adaptability to assembly line production in terms of the advantages of making electrode lines smaller than 100 μm [39]. After years of research and improvement, the line width of the electrode pattern made of photosensitive electrode paste can reach 20 μm and the thickness is 3-4 μm, which can be used for high-performance and high-precision hybrid integrated circuits.

Preparation of Photosensitive Electrode Paste

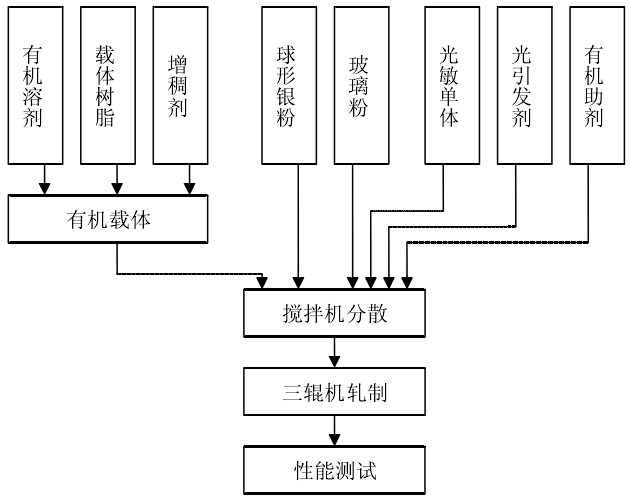

The preparation process of photosensitive electrode paste is shown in the figure, and the specific process is as follows:

(1) Weigh the measured mixed solution of self-synthesized acrylic resin, butyl carbitol acetate and 1,3-butanediol, thickener and other additives into a three-necked bottle at the same time, and mix them evenly Stir and heat in a 90°C Water Bath for 30 minutes to effectively dissolve the resin and obtain the desired organic vehicle.

(2) A planetary defoaming mixer is used for the mixing of the photocuring system and the organic carrier. This equipment disperses without stirring, avoiding the waste of raw materials, and realizes multi-component materials by utilizing the ultra-high acceleration generated by revolution and rotation. evenly dispersed. The specific process is: Weigh the measured organic carrier, photosensitive monomer and photoinitiator, put them in a stirring tank, and carry out planetary mixing at a set speed and time to obtain a mixture of organic carrier-photocuring system, which is called Take care to avoid direct sunlight during measurement.

(3) Weigh the measured spherical silver powder and glass powder into a stirring tank equipped with an organic carrier-photocuring system mixture, and carry out planetary mixing at a set speed and time to obtain a photosensitive electrode slurry. material.

(4) Roll the photosensitive electrode slurry on a three-roll mill, and use a scraper Fineness Meter to test the fineness of the slurry after each rolling pass until the fineness of the slurry is less than 5 μm.