(1) Three-dimensional carbon material modified current collector

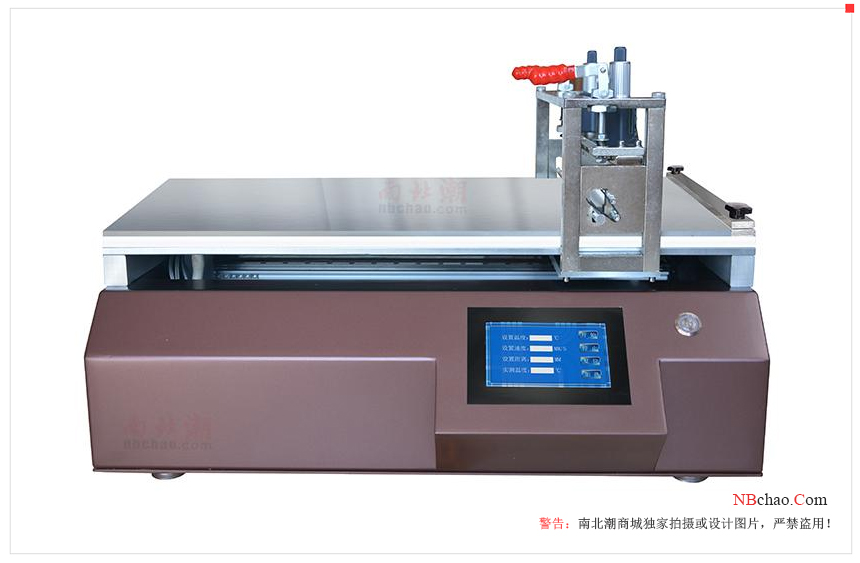

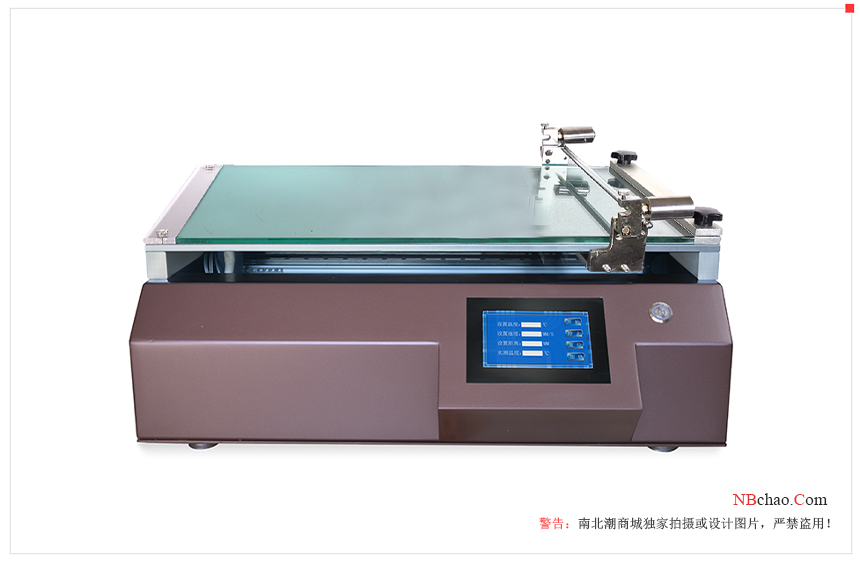

Mix and grind the three-dimensional carbon material and PVDF binder at a mass ratio of 9:1, then add appropriate NMP to mix into a slurry, and apply the slurry evenly on the copper foil through a film coating machine, and vacuum at 60 °C After drying for 12 hours, take out the discs cut into corresponding diameters for later use.

(2) Self-supporting Li/Li3Bi@CC electrode

In the glove box, place lithium metal in a stainless steel container on a heating platform, raise the temperature to 350 °C, then place BiOx@CC on top of the molten lithium metal, and wait until the lithium metal is immersed in BiO x@ CC. Then cut Li/Li3Bi@CC into discs with corresponding diameters for future use.

(3) Interlayer metal lithium electrode

Cut g-C3N 4/CC into discs with corresponding diameters as electrodes, metal lithium sheets as counter electrodes, and add separators and electrolytes to assemble batteries. Li was deposited at a current density of 1 mA cm-2 for 10 h to obtain a g- C3N4/Li/CC electrode with a lithium capacity of 10 mA h cm-2 . Then take it out and wash it with DOL and DME, and dry it for later use.

(4) COF-LZU1 modified electrode

Mix and grind COF-LZU1 and PVDF binder at a mass ratio of 9:1, then add appropriate NMP to mix into a slurry, apply the slurry evenly on the copper foil through a Film Applicator, and vacuum at 60 °C After drying for 12 hours, take out the discs cut into corresponding diameters for later use. Or mix COF-LZU1 with NMP and grind it into a slurry, and then directly coat it on the surface of lithium metal, and use it directly after drying.

(5) Cathode material

S/C complex: Dissolve 60 mg of sulfur powder into 5 mL of CS2, then add 40 mg of carbon-72R (carbot) into the CS2 solution and mix evenly. After the CS 2 evaporated, the mixture was placed in a quartz tube and vacuum-sealed. Then keep it warm at 155°C for 4 hours, and take it out after cooling to room temperature to form the S/C complex . Grind and mix the S/C composite, PVDF adhesive, and Super P conductive graphite at a mass ratio of 8:1:1, add an appropriate amount of NMP to mix into a slurry, and apply the slurry evenly on the aluminum foil through a Film Applicator. Vacuum dry at 60°C for 12 hours, take out the discs cut into corresponding diameters, and weigh them for later use. LCO, LFP positive electrode: Grind and mix the active material, PVDF binder, and Super P conductive graphite at a mass add an appropriate amount of NMP to mix into a slurry, and apply the slurry evenly on the On aluminum foil, vacuum-dry at 60 °C for 12 hours, take out the discs cut into corresponding diameters, and weigh them for later use.