Water-based coatings use conveniently sourced and easily purified water as a solvent to disperse film-forming substances, which can not only reduce costs, but also reduce fire hazards and dust concentrations in the production process, and improve the safety factor of workers' working environments . At the same time, the coating methods of water-based coatings are various and flexible , and can be sprayed, brushed, painted, etc., and it is easy to realize automatic coating.

Waterborne coating method

Paint preparation: Weigh a certain amount of mixed powder paint into the paint container, use a beaker to weigh a certain amount of water ( the mass ratio of water to powder determined according to the experiment summary (0. 65~0. 75): 1, and then add the total mass of the system 1.5% silicone oil emulsion defoamer and 0.06% sodium hexametaphosphate are stirred to form a mixed solution. Part of the mixed solution is poured into the weighed powder coating earlier and stirred at a speed of 400 r/min. Continue to slowly add the remaining mixture to the stirred paint .

Pretreatment of metal substrates: A tinplate sheet with a size of 100 mm × 200 mm × 0.3 mm was polished with 500-mesh water-grinding paper, then ultrasonically cleaned for 1 min; then washed with ethanol and dried for use.

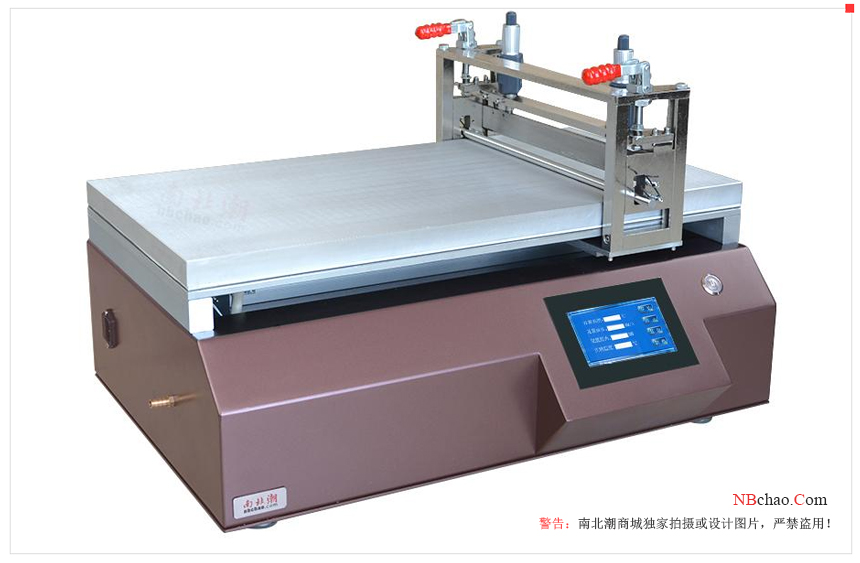

Coating board: fix the pretreated tinplate sheet on the coating machine, place the coating film Applicator on the film coating position, add about 4 g of the prepared coating, and adjust the film coating speed of the coating machine to 10 mm/s to prepare the coating. The thickness of the coating after curing is controlled to be 70-80 μm.

Test panel curing: ① one-step direct curing method, the coating prepared by the water-based coating process directly placed in a hot Forced Air Drying Oven, cured at 180 ℃ for 10-20 minutes, and then aired to room temperature for testing; ② step temperature curing method, the The blastprepared Drying Oven, heated to 180 °C at a rate of 10 °C/min, cured for 10-20 min, and then aired to room temperature for testing.