Lithium-ion batteries have been widely used and are considered as potential high-energy-density chemical power sources. They are not only used in small devices, but also gradually widely used in large devices such as automobiles. Compared with other batteries, lithium-ion batteries have obvious advantages, mainly in the following aspects:

1) High specific energy: The specific energy of lithium-ion batteries is as high as 120Whkg1, which is 2-3 times that of nickel-metal hydride batteries and 3-4 times that of nickel-cadmium batteries.

2) It is safe and pollution-free, does not contain toxic ingredients, is environmentally friendly, and is a green battery.

3) The working temperature range is wide, and it can work at about -20-60°C, which basically meets the needs of daily life.

4) No memory effect, can be charged and discharged at any time, small self-discharge.

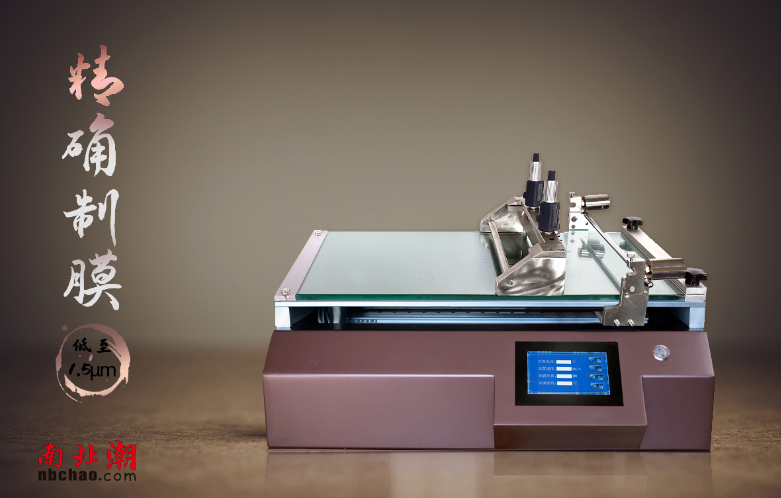

With the technical requirements, industry technicians continue to research and develop higher-performance lithium-ion batteries, and prepare lithium-ion battery films by adding different materials to study their performance. Therefore, experimental coating machines are gradually widely used in the lithium-ion battery industry. Ma, a student from Shanghai University of Engineering Technology, has done research on lithium batteries and wrote a paper "Preparation and Electrochemical Performance of Nano-carbon Fiber Matrix Composite Materials for Lithium-ion Battery Negative Electrodes", from which part of the content of this article is extracted .

It can be seen from the research paper that Ma also used the automatic coating film in the laboratory to prepare the lithium battery negative electrode nanocomposite film. Why is automatic film coating instead of manual film coating used in the preparation of lithium battery thin films?

On the one hand, the film prepared by lithium battery slurry is generally on aluminum foil or copper foil, and the substrate is relatively soft. If the film is manually coated, it is difficult to fix, and the flatness is not good, which will affect the effect and accuracy of the coating film, while automatic coating The film machine has a vacuum adsorption function, which can be well adsorbed and smoothed for soft substrates to ensure the coating effect.

On the other hand, thin films prepared by lithium batteries are generally relatively thin and require high precision. As a new material research, only accurate thin films can obtain accurate test result data in the research of new products and new properties. If the basic materials are inaccurate, there is no reason to talk about high precision in all subsequent tests. The film coating machine can replace the manual film coating, which can ensure the consistency of the coating film under constant speed and constant pressure, and is equipped with high-precision wire rods from the north and south tides to obtain high-precision films.