What is the Taber Abrasion Test?

The Taber wear test refers specifically to a test that measures material wear due to sliding contact. Examples of this type of contact are scratching, grinding and friction. This test is also known as abrasion test or abrasion resistance test, and it is especially suitable for fields such as geology, engineering and metallurgy.

In these technical fields, it is very important to determine the durability of the materials used in production and application. Wear testing also allows manufacturers to test the level of hazard a material may pose in the environment when it erodes.

Generally, there are three types of wear tests. We have flat wear tests where material erosion is caused by surface friction. Next, we perform an edge wear test, testing the material on the edge, which is especially important for the textile industry. Finally, we also have flex wear, where testing is done to determine what happens to the material after it has been folded, bent, or bent.

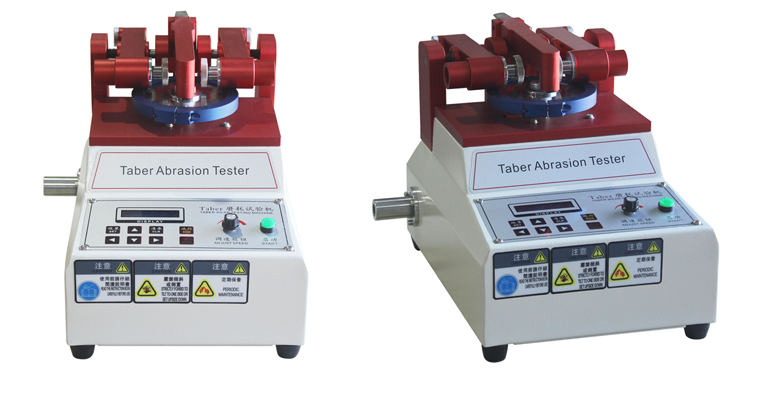

What is a Taber Abrasion Tester?

Typically, the Taber test is used to measure the wear rate and mass loss of a material. Certified systems comply with one of the following industry standards: ASTM D1044, ASTM D3884, ASTM D4060, DIN 53754, DIN 53799, DIN 53109, DIN 52347, and ISO-5470.

Therefore, the test can be used for different purposes, including:

Determine if your company meets production quality standards

Improve the competitiveness of your product with other products

Evaluate materials for functionality, durability and suitability for use in intended products

Reduced risk of failure and associated warranty costs

Optimize limited resources

Also available for R&D and third-party evaluations.

For the Taber test, there are two options for turntable speed - 60 rpm and 72 rpm (revolutions per minute) - and 110 and 220 volt (50Hz) power options.

The Taber machine also features an LCD touch screen interface with an auto shut off option from 0-999,999. It also has optional screen options, including language selection.

An important part of the machine is its vacuum system. On the control panel, there is a key that allows adjustment of the vacuum suction for the test control. There is also a key for "vacuum only" operation, which allows the user to run the machine in vacuum mode only. This mode is useful for cleaning specimens or drive shafts.

With Taber testing machines, you can employ strict controls to obtain highly reliable results. It allows careful selection of the wear quality of the wheel and its consistency. It is also possible to strictly record the load placed on the wheel in grams.

In addition, the machine provides rotating electronic counting and removal of abrasive particles to ensure consistent and reliable results.

All these qualities of the machine ensure the manufacture of defect-free products. Additionally, since the Taber machine provides rapid material testing, using it translates into a low-cost testing operation.

Evaluation of test results

According to the manufacturer's instructions, 4 different methods can be used to evaluate the test results. these are:

visible endpoint

weight loss

volume loss

wear depth

visible endpoint

Certain materials, such as paper, can be evaluated at the point at which they undergo significant physical changes. Here the number of test cycles is considered as a wear index. Other materials that are better evaluated in this way are fabrics, textiles, and polished surfaces.

weight loss

It's just a matter of subtraction, subtracting the weight of the material from the weight before testing. The test involves a density comparison, which means that the wear of two materials with the same density is compared after a similar test has been applied under the same conditions. The wear index for this test is measured in milligrams of weight lost per thousand cycles.

volume loss

For materials of different densities, a good test is the volume loss test. After calculating the difference in weight, the Taber Tester will also provide volume loss.

wear depth

Using the results of any of the above test methods, the user may need to determine the depth of wear to the material during the test. With this, you will need to use an optical micrometer and calibrate to the desired unit of measure.

Due to the many types of materials we test in the lab and the many different variations in load and number of revolutions, there are no typical results to expect. For example, steel records a weight loss in the range of 30 to 60 mg under a test load of 1000 grams for 1000 revolutions.

Regardless of the test used, environmental conditions such as temperature and humidity also need to be considered. Materials are sensitive to these conditions; therefore, specimens need to be conditioned prior to testing, and ambient conditions need to be controlled prior to testing.

These prerequisites should be fulfilled so results can be compared between different samples under similar conditions.

Types of materials used in the Taber test

Taber instruments are capable of testing both rigid and flexible materials. Because of its special ability, this machine has been widely used in various materials. These materials include:

anodized aluminum

High pressure laminate

Decks and Floor Coverings

ceramics

car carpet

coating

Enamel

digital media

leather

luggage

Glass

paints and varnishes

Plastic and paper (ID cards, security gloves, credit cards, etc.)

artificial turf

fabric

interior

Vinyl records, etc.

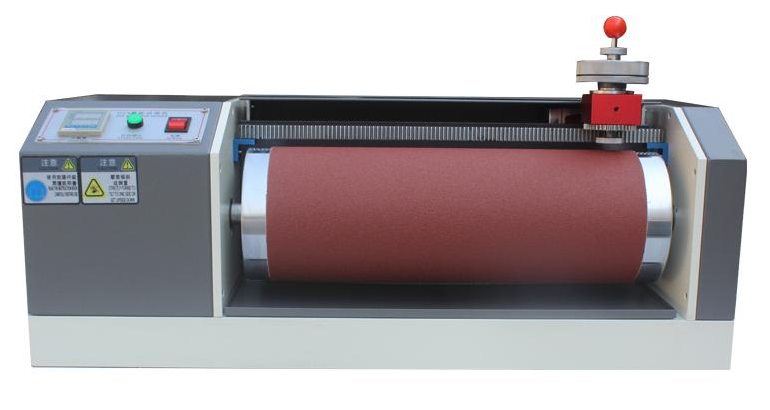

Taber Abrasion Tester Effectiveness – A Practical Test

A Taber Abrasion Tester according to ASTM D4060 is used for testing organic coating materials. Many mechanical components require the materials used in their production to be tested for impact, wear and corrosion resistance. These materials provide wear-resistant coatings on the surface of mechanical components.

We provide you with the details of the test, which consists of three steps - sample preparation, sample testing and evaluation report.

specimen preparation

The specimen is a circular plate with a hole in the center. The diameter of the hole was 6.5 mm and the thickness of the specimen was recorded as less than 6.3 mm.

Coated panels were preconditioned at a temperature of approximately 23 degrees Celsius and a relative humidity of 50% 24 hours prior to testing.

Specimen wear

Under this step, the wear index, weight loss and number of wears per mil are calculated.

In the case of the wear index, the formula used is I = (A – B)1000/C, where A is the weight of the specimen before testing, B is the weight after testing, and C is the number of cycles recorded.

For weight loss, the formula used is simply AB, consistent with the same representation for A and B above.

Finally, wear per mil is also calculated using the formula W = D / T, where D is the number of wear cycles required to abrade the coating and T is the coating thickness reported in mil units. 1 mil is equivalent to 0.001 inches or 0.00254 centimeters.

Evaluation Report

Taber equipment provides several results for testing and wear evaluation under ASTM D4060. These include:

Temperature and relative humidity during the conditioning phase and the actual test

Coating thickness (wear cycle is also specified)

grinding wheel used

Applied load

Wear index, weight loss and wear cycles for each mill

When stating the results in a material specification or when specified in a contract, it is also necessary to state whether the material tested failed or passed the standard. This criterion may include loss of gloss, loss of coating, loss of color, pilling condition and other changes in appearance.

Repeatability Tips for Taber Abrasion Testers

To ensure the repeatability of reliable testing with this machine, there are a few things you can do:

Facing the wheel again before the test

Check the wheel surface after a long test

Adjust the vacuum nozzle each time a new specimen is tested