The Vickers hardness test is designed to ensure that a component, material or material treatment is strong enough to resist constant stress after being part of a machine. It's one of the more reliable hardness-testing models that companies use to determine whether certain parts are hard enough for a particular object.

As of now, there are a variety of devices that help companies perform this hardness testing. But, of course, it would be better to find a cost-effective Vickers Hardness Tester to invest in. But before you start looking, you need to understand some concepts.

What exactly is a Vickers hardness test?

The Vickers hardness test is one of several hardness tests used by quality assurance professionals to determine the compatibility of a material or component in a machine. The Vickers hardness test is unique in that it is specifically designed for testing objects that do not have a large surface area or are relatively small in size. Therefore, it is also called microhardness test.

The concept of testing is very simple. The test instrument will measure the strength of the part by stressing it with a fixed load, which ends with a diamond-tipped indenter. The strength of a component measured under the Vickers hardness test depends on the size of the indentation left on it after sufficient pressure is applied.

As a rule of thumb, the size of the indentation is inversely proportional to the strength and resistance of the material. Simply put: the smaller the indentation left, the more durable the component.

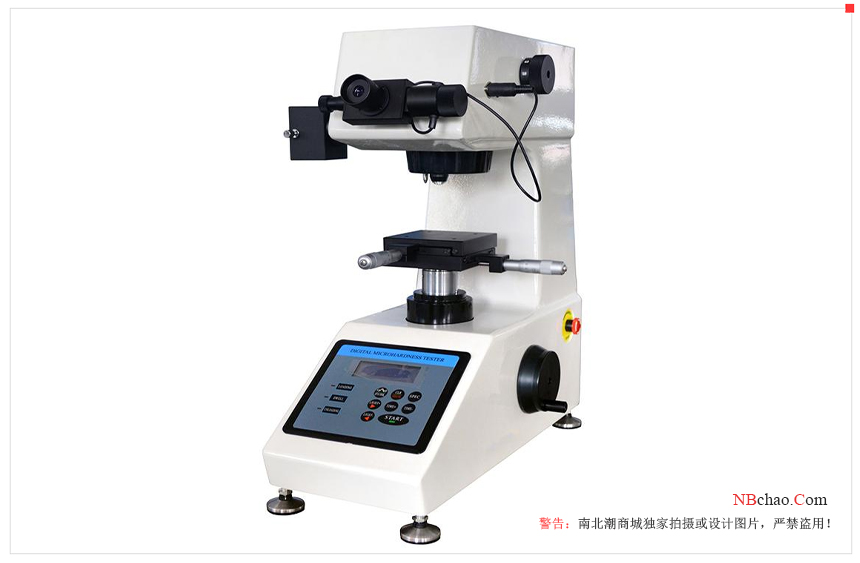

Each manufacturer of analog Vickers Hardness Testers has its own variation of the basic design to meet specific sample sizes and other specifications. However, the general concept of the test will remain from one Vickers Hardness Tester to another.

Durometer type

There are basically two types of hardness testing options. these are:

A. Benchtop – Usually classified as a traditional durometer. These fixtures are designed for non-destructive testing of materials. These materials, also called coupons, are placed on the Tester's table, called the anvil, to be tested. These units are designed to be located in a single location in the laboratory.

A key feature of these Testers is their weight. Benchtop Testers may weigh at least 50kg and need to be mounted on the workshop floor. Still, bench Testers are fairly reliable, as they rely on traditional methods of Graduation material hardness.

B. Portable - Unlike bench Testers, portable durometers are lightweight, manually portable, and capable of testing materials on different hardness scales. Therefore, the main advantage brought by a portable Tester is the ability to bring the Tester to the test material, not the other way around. As a result, operators no longer need to collect samples from the field, transport them and feed them into the instrument. Portable device types are especially useful for large and irregularly shaped specimens that cannot be mounted on a traditional benchtop Tester.

Portable Testers can be used as analog and electronic devices according to the operator's preference

supply. Generally, electronic devices are more accurate and minimize the human error element. Each portable Tester will have a number of features that extend its usefulness to the operator. This includes the ability to save measurements and transfer them to a computer for further processing.

Which device type is better?

Benchtop and portable Hardness Testers each have advantages and disadvantages. It's up to you to weigh each feature they bring and decide which device is right for you.

If the workshop in question involves many manufacturing processes that will involve the movement of material from different facilities, then a benchtop Tester would be desirable. On the other hand, if the workshop is more about quality assurance and control, then portable equipment is more advisable.

If cost is an issue, the more affordable Vickers Hardness Testers will be the portable versions. These variants are less expensive to purchase and include several features that enhance the operator's experience with the equipment. But it is worth noting that the portable Vickers hardness test performed by the ultrasonic Hardness Tester is a relative measurement method. If your specimens are smaller or more suitable for a metallographic lab and your budget allows, a benchtop solution is the more accurate choice.

Finally, there is the element of human error, as this is unavoidable in any process-based activity. You need to invest in a device that actually helps the operator avoid mistakes, especially when interpreting measurements. Portable devices have an advantage in this regard because they simply give the measurement rather than having the operator read and interpret what is indicated on the scale.

Is it recommended to use a used Tester?

While you're better off just buying a new Tester, there are no rules that prevent you from buying a used Tester. Many durometers are built to last and therefore maintain reliability even after years of use.

In most cases, if you choose to buy used equipment, analog equipment is recommended. They have simpler systems, which means they tend to last longer and are easier to repair if they break down. As with digital Testers, the repair process can become expensive and complicated.

You should also consider the role you will be taking on when purchasing these refurbished machines. At best, they serve as backup test instruments in case your main machine fails.

However, if you can find a used Tester that's been kept particularly well, you can always combine it with a new one. This way, you can refer to different hardness scales when testing materials during production.

one final consideration

When deciding on a cost-effective Vickers Hardness Tester, one should also keep in mind that after several years of use, these instruments will eventually have to be replaced. This is despite the fact that some Testers are designed to last. Eventually, they will have to be replaced by newer, more reliable Testers.