Printing operations use many different substrates - some better than others.

Popular substrates today include rigid vinyl PVC, polypropylene and/or BOPP, and polyester (PET). The advantage of these plastic substrates over traditional substrates is their durability. Plastic resists damage from water or chemicals and is a more affordable option for many applications.

Plastic substrates produce high-quality prints if you know how to print on plastic film. High-quality print is vibrant and full of life, which will increase your sales by engaging your audience.

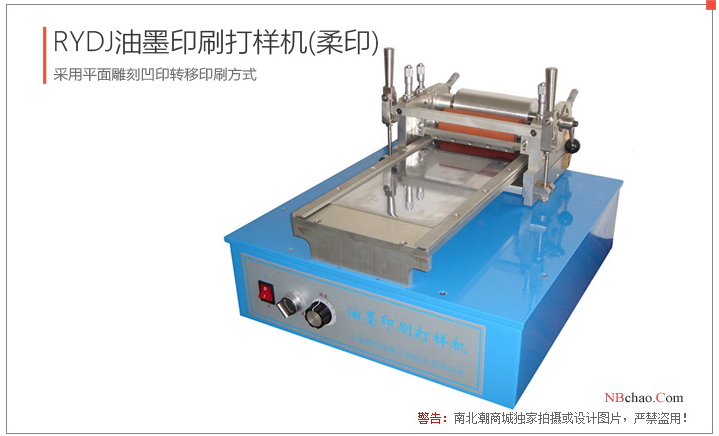

Flexographic printing is one of the simple methods for printing on plastic film substrates. Here's how it's done:

Choose Flexo

Some quick background: flexo printing shares a common origin with traditional printing methods. Before we delve into the nuances of printing on plastic film substrates, it is important to understand the basics of the flexo printing process.

To print on plastic film, apply ink to an anilox roller that works with a drawdown blade. This controls the process of producing a uniform ink layer. The surface of the roller has small cells placed at specific angles to transfer ink to the image carrier.

Next, an anilox roll deposits ink onto the surface of the image carrier wound on a rotating drum. The plastic substrate sits on a backup roll or CI drum, and the image carrier transfers ink and print evenly to the substrate.

As the name suggests, flexo printing is very flexible in terms of application. It produces prints at high speeds, reducing press downtime and extending press run times .

How to Print on Plastic Film: 6 Factors to Remember

There are several factors to consider when printing on clear plastic film.

1. Surface tension

Surface tension is the force in liquids that allows them to act as if surrounded by an elastic membrane . This happens when the molecules of a liquid stick to each other, creating a bead effect.

Surface tension affects the wettability of ink on a surface and is expressed in dynes/cm. For successful printing, the surface tension of the ink needs to be lower than that of the image carrier in order for it to transfer properly from the anilox roll to the surface of the image carrier.

2. Surface energy

Surface energy is the residual energy of the surface of a plastic substrate compared to its size. It is measured in Joules/square meter. meter.

When you choose the type of plastic substrate you want for your final packaging to be used in flexo printing, it is important to know its surface energy to avoid costly and time-consuming printing defects in the end.

Most plastic substrates tend to be easily treated to increase the surface energy, ensuring that it is higher than that of the ink - allowing the ink to 'stick' to it and transfer properly.

3. Wettability

This is the ability of the ink to wet the surface you are printing on. It is affected by the surface tension of the ink and the surface energy of the substrate. This can also be affected by the polar quality of the image carrier.

In summary, wettability affects how well the ink spreads/spreads on the surface.

When printing on transparent plastic films, the importance of good ink-substrate interaction to ensure high-quality prints cannot be overemphasized. This results in smoother coverage, fewer pinholes and overall fewer print defects.

4. Ink selection

Choose an ink with a surface tension 10 dynes lower than the surface energy of the plastic film. This makes it easy for image carriers to be in between.

There are things you can do to affect the surface tension of the ink - such as adding alcohol or other treatments. However, as mentioned above, it is easier and more efficient to dispose of plastic film where possible.

This will ensure good wetting and high quality prints.

5. Distortion

When flexo printing, you can achieve zero distortion by choosing round flexo sleeves with 100% engraving size.

Elastomeric hybrid sleeves can be manufactured to be more durable than photopolymer plates and more flexible on substrates.

6. Time and money

For large-scale industrial printing, efficient work is the key to maximizing profits.

You need to do the calculations properly so you don't have to go back and re-do it just because something is out of proportion. Precise treading on the plastic film is easy to achieve with a well-made elastic sleeve.