The density of petroleum products increases with the increase of the content of carbon, hydrogen, oxygen, sulfur and other elements in its components. Therefore, oil products containing more aromatics, colloids and asphaltenes have a high density, while oils containing naphthenes The density of the oil with more alkanes is in the middle, and the density is the smallest. Therefore, according to the density (or specific gravity) of petroleum products, the type and composition of oil products can be judged to a certain extent . One of the instruments.

In this paper, the high-precision automatic density meter WMD-330 (using the U-shaped vibrating tube detection principle) produced by Shanghai Yidian Physical and Optical Instrument Co., Ltd. is used to directly detect the standard density of oil in the finished oil tank, eliminating the need for oil " The two steps of " apparent density" and "observation of temperature" measurements make it easier for oil metering personnel to quickly calculate the actual weight of the currently stored oil in the product oil tank.

1. Reference standards

1. Determination of density of petroleum and liquid petroleum products (densitometer method) GB/T 1884-92

2. Laboratory determination method for density of crude oil and liquid petroleum products GB/T 1884-2000

3. Petroleum meter GB/T 1885-1998

2. Measurement steps

1. Use a dipstick or other liquid level measuring instruments to measure the oil height of the oil in the oil tank (h oil)

2. According to the oil height and oil tank volume conversion table, find out the volume of the oil in the current tank (V oil)

3. Take a small amount of oil sample and inject it into the automatic density meter. Control the temperature to 20°C and measure the standard density of the oil (ρ standard)

4. According to the standard density and the oil temperature of the oil in the tank, calculate the gravimetric density (ρ meter) of the oil in the tank at the current temperature

5. Multiply the weight density by the current volume of the oil in the tank to get the weight of the oil in the tank (m=ρ is V oil)

3. Instrument use

1. Start up: After starting up on the same day, you need to wait for the internal temperature of the instrument to equalize before starting to measure

2. Calibration: When starting up for the first time, it is recommended to use dry air and high-purity water to calibrate the instrument

3. Temperature control: The instrument adopts semiconductor refrigeration, PWM temperature control, and high-precision constant temperature control

4. Sample injection: U-shaped quartz glass tube, inject 2~3ml sample into the syringe, no air bubbles

5. Measurement: After the temperature of the sample to be measured is balanced, select the measurement mode to start the measurement

6. Data: Multi-parameter data conversion, measurement results are automatically saved, and can be exported by U disk

7. Cleaning: The air pump discharges the sample, and the U-shaped tube is cleaned with petroleum ether and absolute alcohol

8. Drying: The U-shaped glass tube needs to be cleaned repeatedly and decondensed with dry air

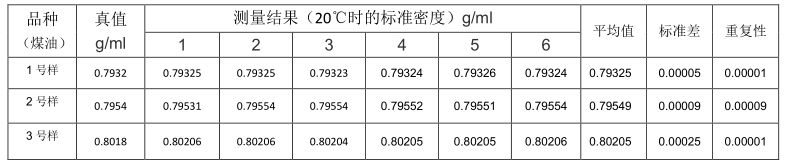

4. Measurement data

5. Product Features

1. The amount of sampling is small, only 2~3ml of sample is needed to measure a sample, which is convenient

2. After the temperature is balanced, the measurement time is short, and it only takes about 1 minute to measure a sample, which is fast

3. The instrument comes with temperature control, no need to measure "apparent density" and "observation temperature"

4. The standard density can be measured directly, reducing the conversion and table look-up process, simple

5. Easy to operate, high precision, suitable for high frequency and large batch inspection, effective

6. Equipped with a variety of communication interfaces, data can be saved, exported and printed, accurate

6. Influencing factors

1. Effect of temperature: the measurement temperature affects the density of the oil and the geometric size of the U-shaped tube, and precise temperature control is required

2. Effect of bubbles: if there are bubbles in the oil injected into the U-shaped tube, the resonance frequency will increase and the density will decrease

3. Viscosity effect: The viscosity of the oil affects the resonance frequency of the U-shaped tube. If the viscosity is too high, it will not be able to measure accurately

4. Pressure influence: The pressure of the sample will affect the geometric deformation of the U-shaped tube, as well as the density of the sample

5. Time influence: due to the volatile nature of refined oil, it is necessary to test as soon as possible after the temperature control of the sample injection is stable.