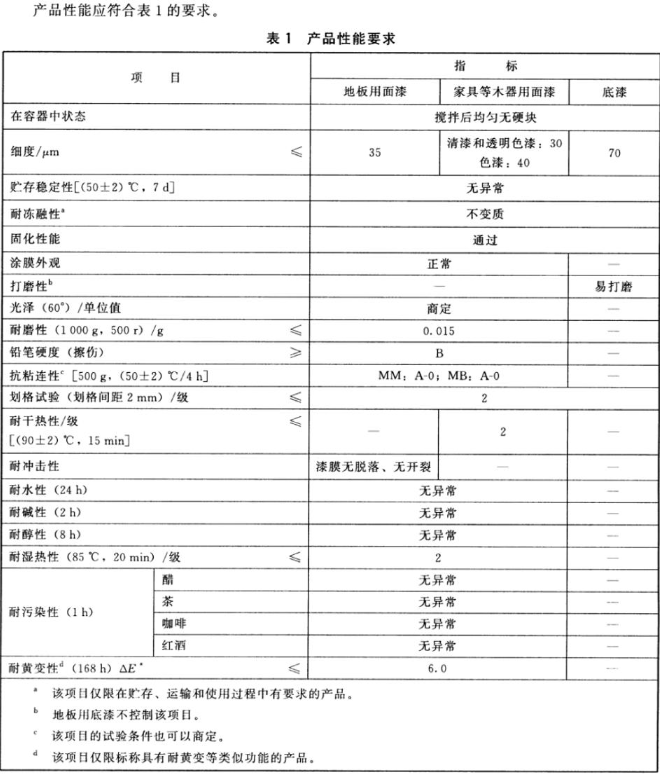

Water-based ultraviolet (UV) curing wood coatings are suitable for water-based UV-curing wood coatings composed of UV-curing resins, photoinitiators, water and other ingredients. The product is suitable for the decoration and protection of indoor wooden floors, furniture and other wood products. So what performance can it detect? What about standard requirements? Today we will introduce the regulations of HG/T 5182~5183-2017 on the detection of water-based ultraviolet (UV) curing wood coatings. Before testing, we need to understand the classification of water-based ultraviolet (UV) curing wood coatings. According to its main use, it can be divided into top coats for floors, top coats and primers for furniture and other wood

Item detection

1. State in the container: First, we open the container and stir with a spatula or stirring rod, and allow precipitation at the bottom of the container. If it is easy to mix evenly after stirring, it is rated as "homogeneous without lumps after stirring".

2. Fineness: In the test, the topcoat for flooring needs to reach the standard of ≦35/μm to be considered up to the standard; the topcoat for furniture and other woodware must reach: varnish and transparent paint: 30/μm, for color paint: 40/μm, it is considered to be up to the standard; and the primer needs to reach ≦70/μm, to be considered up to the standard.

3. Storage stability: Before testing, we need to put about 0.5L sample into a well-sealed dark plastic tank. The northern and southern tides remind you: about 10% of the space should be left in the tank. Put it into (50±2)°C constant temperature Drying Oven after sealing, take it out after 7 days, and place it in (23±2)°C for 3 hours, check the "state in the container". If there is no significant difference between the test results after storage and those before storage, it is rated as "no abnormality".

4. Freeze-thaw resistance: We need to carry out 3 cycles of tests. If after the test, the floor topcoat, furniture and other wood topcoat and primer do not deteriorate, it is rated as "no abnormality".

5. Curing performance: Under the curing conditions agreed by both parties, use a single UV lamp or a UV curing device for the production line to test. If the test result shows that the coating film can dry, it can be judged as "pass".

6. Appearance of coating film: The test requires visual observation of the sample under scattered sunlight. If the coating film is uniform and there is no coating film pathology such as sagging, blooming, pinholes, cracking and peeling, it is rated as "normal".

7. Grinding performance: We use No. 400 white sandpaper and dry-grind 10 times by hand (one reciprocation counts as one time). If the coating film is easy to polish to a flat and smooth surface, it is rated as "easy to polish".

8. The gloss index test should be carried out under the curing conditions agreed by both parties, and there are no other requirements.

9. In the test of abrasion resistance, if the test results show that the abrasion resistance of the top coat for flooring and furniture and other woodware are all ≦0.015/g, it will be rated as "standard".

10. Pencil hardness: If the pencil hardness of the topcoat for flooring and furniture and other woodware is ≥ B, it will be rated as "standard".

11. Anti-adhesion: We must use a weight with a load of 500g and a diameter of 70mm to test at a temperature of (50±2)℃, and the test time is 4h. If after the test, the index of the finish paint for flooring is MM: A-0, and the index of finish paint for furniture and other woodware is MB: A-0, then it is rated as "standard".

12. Cross-cut test: If after the test, the cross-cut distance is 2mm, it will be rated as "standard".

13. Resistance to dry heat: We must conduct the test in an environment with a temperature of (90±2)°C, and the test time is 15 minutes. If the test result shows that the dry heat resistance of the topcoat for furniture and other woodware is ≦2, it will be rated as "standard".

14. Impact resistance: If after the test, the impact resistance of the floor finish is that the paint film does not fall off or crack, it is rated as "standard".

15. Water resistance: the test solution required for the test is distilled water. We have to take the middle part of each plate in the test area and put 5 layers of filter paper on it. Notice. During the test, the filter paper should be kept moist, and if necessary, apply Vaseline to the contact part of the glass cover and the test plate to seal it. After 24h, the filter paper was removed, blotted dry, and left for 2h. Then observe visually under diffuse sunlight. If 2 of the 3 test panels have no coating film pathological phenomena such as blistering, cracking, peeling, obvious discoloration and obvious gloss change, it is rated as "no abnormality".

16. Alkali resistance: The test solution required for the test is 50 g/L sodium carbonate solution, the test time is 2 hours, and the test is left for 1 hour before observation.

17. Alcohol resistance: the test solution required for the test is 70% ethanol aqueous solution, the test time is 8 hours, and the test is left for 1 hour before observation.

18. Moisture and heat resistance: the test temperature required for the test is 85 ℃, and the test time is 20 minutes. If after the test, the moisture and heat resistance of the floor finish and the furniture finish are all ≦2, it is rated as "standard".

19. Pollution resistance: The test time is 1h, and it is observed after 1h after the test.

a. Vinegar resistance: The test solution required for the test is brewed vinegar, and the test index is agreed upon by both parties according to the actual situation, and there is no other requirement.

b. Tea resistance: The test solution required for the test is black tea water. We need to add 250 mL of boiling water to 2 g of black tea, and after standing at room temperature for 5 minutes, immediately use tea water for the test. The test indicators shall be negotiated by both parties according to the actual situation, and there are no other requirements.

c. Coffee resistance: The test solution required for the test is 40g/L coffee solution (without sugar), we need to add 250 mL of boiling water to 10g of coffee, and after standing at room temperature for 5 minutes, immediately use the coffee solution for the test. The test indicators shall be negotiated by both parties according to the actual situation, and there are no other requirements.

e. Resistance to red wine: the test solution required for the test is red wine. The test indicators shall be negotiated by both parties according to the actual situation, and there are no other requirements.

20. Anti-yellowing property: If after the test, the anti-yellowing property of top coats for flooring and furniture and other woodware are all ΔE≦6.0, then it is rated as "standard".