Epoxy primer is a two-component, low-VOC, high-solids, fast-curing epoxy primer containing zinc phosphate antirust pigments. It is mainly used for sealing and protecting the surface of metal, concrete and other substrates. It is suitable for room temperature curing two-component solvent-based coatings with epoxy resin as the main film-forming substance, not suitable for epoxy resin primers containing zinc powder, glass flakes and asphalt.

Today we will introduce the regulations of HG/T 4566-2013 on epoxy resin primer. Before testing, we need to understand the classification of epoxy resin primers. We divide it into products for metal substrates and products for concrete substrates according to the application. Products for metal substrates are divided into two types: general primer and sealing primer; products for concrete substrates are divided into two types: varnish and color paint.

Item detection

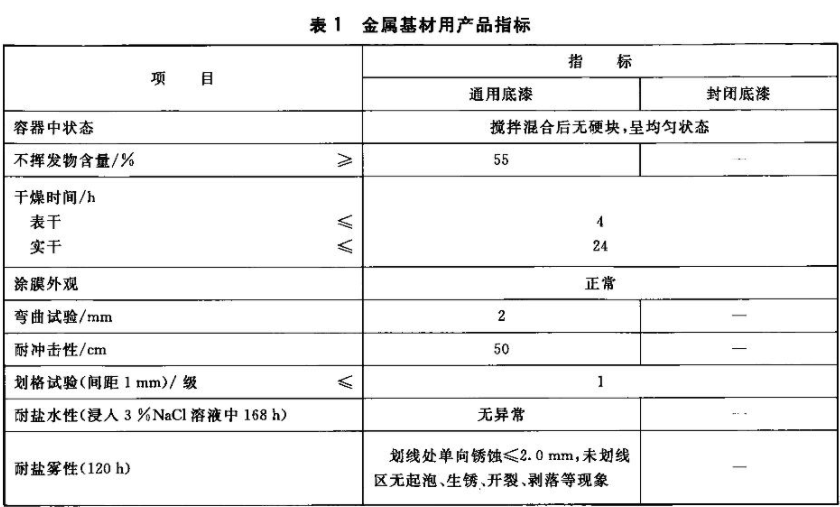

1. Detection indicators in products for metal substrates

a. State in the container: First, we open the container and stir it with a spatula or stir bar, and allow precipitation at the bottom of the container. If the universal primer and the sealing primer are easy to mix evenly after stirring, it is rated as "uniform without hard lumps after stirring", which meets the index.

b. Non-volatile matter content: If the non-volatile matter content of the general primer is ≥ 55%, it is regarded as meeting the standard.

c. Drying time: If the surface drying time of the universal primer and the sealing primer is ≦4h, and the hard drying time is ≦24h, it is considered to be up to the standard.

d. Appearance of coating film: The test requires visual observation of the sample under scattered sunlight. If the coating film is uniform and there is no coating film pathology such as sagging, blooming, pinholes, cracking and peeling, it is rated as "normal".

e. Bending test: If the bending index of the universal primer is 2mm, it is regarded as up to standard.

f. Impact resistance: If the impact resistance index of the universal primer is 50cm, it is regarded as up to standard.

g. Cross-cut test: If the cross-cut level of the universal primer and the sealing primer is level 1, it is regarded as up to standard.

h. Salt water resistance: We immersed the universal primer sample in 3% NaCl solution for 168 hours, took it out, rinsed it with water and wiped it dry, and observed it visually under scattered sunlight. Rust, cracking, peeling, powder falling, obvious discoloration, obvious loss of gloss and other pathological phenomena of the coating film, it is rated as "no abnormality".

i. Salt spray resistance: We draw a line parallel to the long side of the test plate in the middle of the universal primer sample for testing. The unidirectional corrosion at the line is ≤ 2.0 mm, and there is no blistering, rust, or cracking in the unlined area . Peeling and other phenomena, it is rated as "qualified".

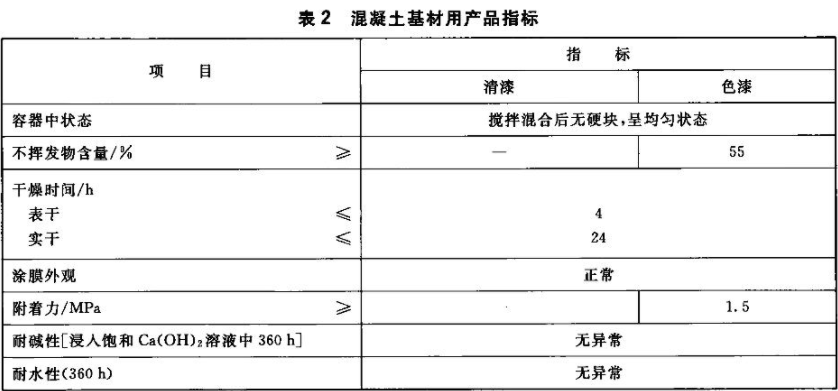

2. Detection indicators in products for concrete substrates

a. State in the container: First, we open the container and stir it with a spatula or stir bar, and allow precipitation at the bottom of the container. If the varnish and paint are easy to mix evenly after stirring, it is rated as "uniform without hard lumps after stirring", which meets the index.

b. Non-volatile matter content: If the non-volatile matter content of the paint is ≥ 55%, it is regarded as meeting the standard.

c. Drying time: If the surface drying time of varnish and color paint is ≦4h, and the hard drying time is ≦24h, it is regarded as up to standard.

d. Appearance of the coating film: the test requires visual observation of the varnish sample and the color paint sample under diffuse sunlight. If the coating film is uniform and there is no coating film pathology such as sagging, blooming, pinholes, cracking and peeling, it is rated as "normal".

e. Adhesion: We use a test column with a diameter of 20 mm for testing. If the adhesion of the paint is ≥1.5MPa, it is considered up to standard.

f. Alkali resistance: We immerse the varnish sample and the color paint sample in the saturated Ca(OH)2 solution for 360 hours, and the coating surface is 5mm above the liquid surface. If there are bubbling, cracking, peeling and other pathological phenomena of the coating film, it is rated as "no abnormality".

g. Water resistance: We put the coating surface of the varnish sample and the color paint sample upward and half into the water, and the coating surface is 5 mm above the liquid surface. After 360 hours, take it out and observe it visually. For example, there are two of the three test pieces If there is no bubbling, cracking, peeling and other pathological phenomena of the coating film, it is rated as "no abnormality".