This article is mainly an excerpt from "The Effect of Homogenization Treatment on the Microstructure and Properties of Lithium-based Grease" by Ren Jia and other scholars. In the experiment of the paper, a three-roll mill was used to grind and homogenize lithium-based grease.

The three-roll mill is an important equipment for the homogenization of grease. With the development of electromechanical control and roller grinding technology, the three-roll mill can realize the precise regulation of the roller spacing at the micron level. In order to clarify the effect of the roller spacing of the three-roll mill on the microstructure and performance of lithium-based grease, scholars used different roller spacing to grind lithium-based grease, characterized the microstructure of the thickener of the sample, and tested the cone thickness of the sample. Penetration, dropping point, mechanical stability, colloidal stability and rheological properties, and the correlation between microstructure and performance was analyzed.

How to process grease with a three-roll mill?

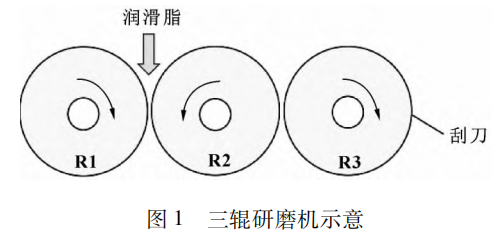

In the experiment, the lithium -based grease samples prepared above were divided into 5 parts , 4 of which were ground by a three-roll mill ( EXAKT 80E PLUS ) with precisely adjustable roller spacing . The schematic diagram of the three-roll mill is shown in Figure 1 .

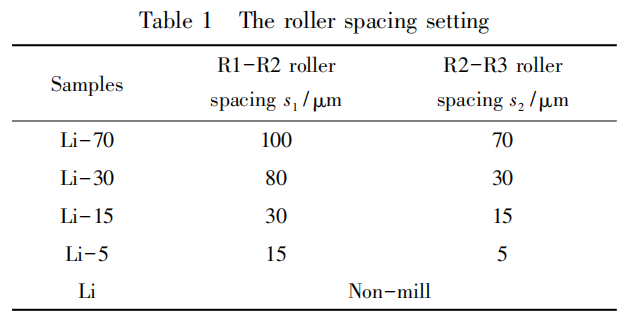

See Table 1 for the setting of the roller spacing and corresponding sample names for grease grinding treatment. The main references for the setting of the grinding roller spacing are [16-17]. The rotating speed is 300 r/min.