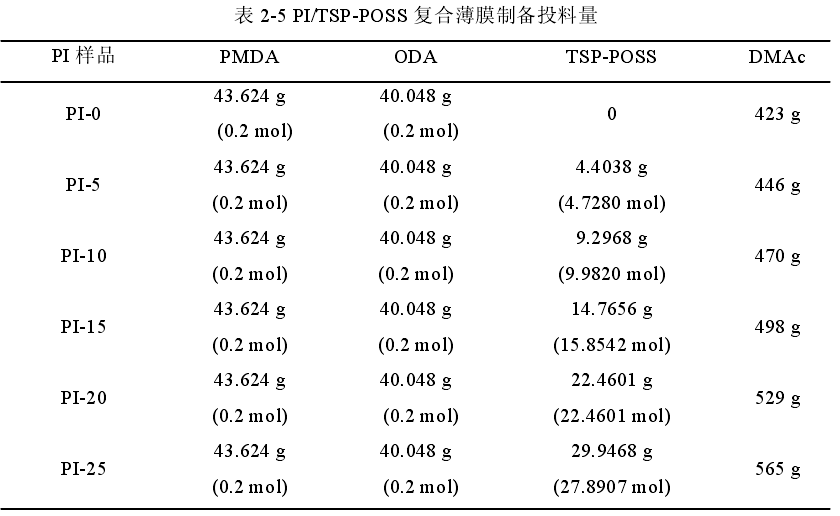

Pour the prepared PAA/TSP-POSS solution onto a clean glass plate, and use an automatic Film Applicator to coat the film, and control the thickness of the wet film and the final cured film by controlling the width of the scraper slit. Subsequently, the glass plate was placed in a clean Drying Oven, and the temperature was programmed according to 80°C/3h; 1209C/1h; 150°C/1h; 180°C/lh; 250°C/1h; 300°C/1h. Naturally cool to room temperature, soak in clean deionized water, remove the film and dry at 120 °C under normal pressure, and obtain a PI/TSP-POSS composite film after natural cooling. The numbers of PI/TSP-POSS composite films with POSS content of 0, 5 wt%, 10 wt%, 15 wt%, 20 wt%, 25 wt% are PI-0, PI-5, PI -10, PI- 15. PI-20 and PI-25. The dosage of each resin system is shown in Table 2-5.