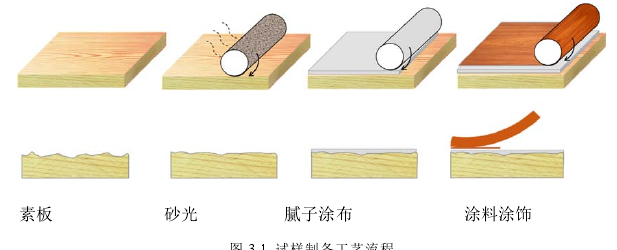

Substrate preparation

After the board is sawed, it is made into a substrate sample with a specification of 300mm (L) x 200mm (T) x 20mm (R) through processes such as planing and planing . The substrate preparation process is shown in Figure 3-1.

The surface roughness of the sample is 3.456um. To ensure that the surface of the substrate is dry and free of dirt polish the substrate along the wood grain to make the surface smooth and clean the dust; The influence of uneven pores on the experiment , roll-coat water-based UV putty on the sanding substrate, the coating amount is 25-35g/m2, and the roller is evenly scraped and repaired. Semi-dry curing by UV putty double lamps, the light curing energy is 80-120mj/cm2. After the putty is cured, sand it with 350# sandpaper . Roll the water-based UV putty again, and polish the test piece with 400# sandpaper after semi-drying and curing. The dust is removed and dried, and then left for the experiment.

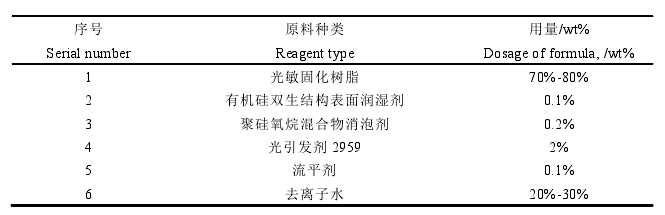

paint preparation

According to 2.5.1 and 2.5.2, the PUA resin, wetting agent, defoamer, photoinitiator, and leveling agent have been screened out. According to 2.5.3, the preparation process is optimized, and the photoinitiator (2%), Foaming agent (0.2%), wetting agent (0.1%), etc. Store away from light after dispersion. The solid contents of the prepared waterborne UV coatings were 70wt% and 80wt%, respectively.

Sample coating

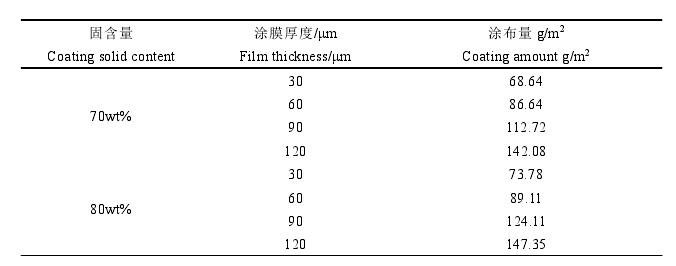

Usually the wet film thickness of water-based wood coatings is 30um~120um, otherwise it is prone to defects such as uneven coating and bubbling. Using an automatic coating machine, take the uncoated test piece as the control sample, and adopt the one-time coating method to investigate the coating thickness (wet film thickness 30um, 60um, 90μm, 120μm), temperature (35°C, 45C, 55°C) "C, 65"C) Variation of film drying time. Two groups of high solid content coatings of 70wt% and 80wt% were selected to achieve fast curing of wood coatings.

Weigh the mass of the coating sample, and when coating the wet film, fix the plain board on the operating table of the automatic film coating machine, load 1.0kg weights at both ends of the automatic film coating machine support, and use the water-based UV wood coating prepared in 3.3.2 Coat the sample along the grain, place the four-sided coating rod on the front end of the bracket, and evenly coat the coating on the contact surface between the four-sided coating rod and the sample, and the coating speed is 80mm/s. The coating amount is determined by the height of the gap at the bottom of the four-sided coating rod. Weigh the coated sample on the balance and subtract it from the uncoated plain plate to calculate the coating amount. Table 2-7 shows the coating amount data of different coating film thicknesses when the solid content of the coating is 70% and 80% respectively .