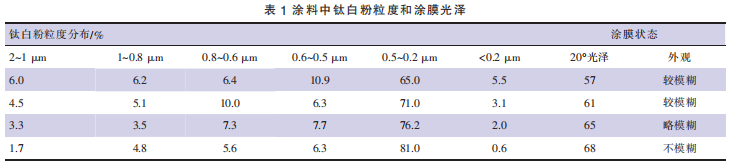

There are many factors that affect the gloss of the coating film, such as resin, pigment and filler, dispersant, pigment-base ratio, substrate, coating color, surface smoothness, etc. Pigment is only a kind of paint component, the paint itself is dull, and the coating film has luster, but the influence of pigment characteristics in actual production determines the gloss of the coating film [2]. Titanium dioxide is an important pigment in coatings, its particle size, surface treatment, dispersibility, oil absorption, and the amount added in the coating (pigment volume concentration, PVC) and other parameters have a certain impact on the gloss of the coating.

In this paper, an automatic film coating machine will be used to prepare a film, and the factors affecting its gloss will be studied.

Method for preparing titanium dioxide thin film by automatic coating machine

Weigh glass beads, acrylic resin solution (solid content 26%) and titanium dioxide samples (pigment volume concentration PVC: 16%) of the same quality, put them into a fully automatic mixer for dispersion, and place the dispersed paint in an automatic On the film coating machine, use a paint Film Applicator to scrape on the mirror glass plate at a fixed pressure and a speed of about 100 mm/s to form a flat paint film. After drying for 16 hours under the conditions of temperature (23±2)°C and relative humidity (50±5)%, the glossiness was measured. The measurement basis is "GB/T 9754-2007 Determination of 20°, 60° and 85° specular gloss of paint films of paints and varnishes without metallic pigments".