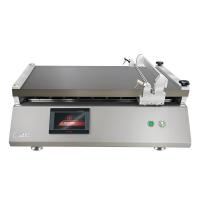

The active material, binder (PVDF), and acetylene black (AB) prepared in the experiment were mixed in a mortar according to the mass ratio of 70:15:15, and dry-milled for 15 minutes, and then an appropriate amount of N-methylpyrrolidone was added dropwise Dissolve PVDF in (NMP) solvent , and manually grind for 30 minutes to obtain a uniform and viscous negative electrode slurry, and then use an automatic film coating machine to evenly on a clean copper foil (thickness 10-15 um). Dry in a vacuum oven for 12 h to effectively volatilize the NMP in the slurry. After the fully dried copper foil coated with the slurry was taken out, a disc with a diameter of 12 mm was cut out with a cutting machine , and the electrode sheet required for the battery was obtained. The electrode sheet needs to place a small piece of aluminum foil up and down in the tablet press and apply a pressure of 10 MPa to ensure full contact between the electrode material and the current collector (copper foil), prevent it from falling off during the cycle increase the conductivity of the electrode sheet and stability. At the same time, a current collector disc of the same size was punched out at the position where the copper foil was not coated with active material , and used to determine the weight of the blank current collector. After obtaining the mass of the active substance on a precision electronic balance , put it into a sealed bag (the sealed bag is not sealed), and transfer it to a glove box filled with argon (H2O<0.1 ppm, O2<0.1ppm) for button lithium-ion battery Assemble.

In the process of assembling the battery, the above-mentioned electrode sheet was used as the working electrode, the pure lithium sheet was used as the reference electrode and the counter electrode, and Celgard 2400 separator was used to dissolve 1 molL-1 in ethylene carbonate (EC) and diethyl carbonate ( DMC ) solution (volume ratio 1:1) and LiPF6 with 5% fluoroethylene carbonate (FEC) added as electrolyte. The half- cells are assembled into a button-type 2025 type, and after the assembly is completed, they are packaged by a battery packaging machine.