The battery separator is also a key component of the battery. The battery separator does not participate in the electrochemical reaction. It mainly isolates the positive and negative electrodes and provides a channel for lithium ion transmission. The separator has a very important impact on the performance and safety of the battery. For interface structure, internal resistance, Capacity and cycle performance, some separators with thermal closure function can also form closed pores when the battery is overheated, blocking the conduction of current and ensuring the safety of the battery.

The thickness of the separator will affect the internal resistance of the battery. The thicker the separator, the greater the internal resistance, and the smaller the thickness, the smaller the internal resistance. Therefore, it is necessary to control the thickness of the diaphragm in an appropriate range. If the thickness is too small, it cannot guarantee the mechanical strength of the separator during the preparation and assembly process, or there will be pinholes on the surface of the separator and it will be easily torn, and the battery may be short-circuited when it is dangerous. At present, the thickness of commercial battery separator is 25um.

Lithium-ion battery separators are divided into three categories: polymer separators, non-woven separators, and composite separators. Among them, polyolefin separator is the most widely used battery separator.

In order to improve the absorptivity of polyene to the electrolyte through the separator, methods of modifying polyene, such as polymer coating and electrolyte copolymerization, are used. By coating inorganic ions on the surface of the polyolefin separator material, or using polymers to graft and modify the polyolefin separator to improve the thermal stability of the separator and increase the retention of the electrolyte. Zahid Ali Ghazi combined conductive MoSz on the surface of Celgard separator, which can promote the diffusion of lithium ions and convenient lithium transfer. It can be used as a lithium-sulfur battery separator to inhibit the shuttle of polysulfides, thereby improving the long-term cycle stability of the separator. . Pengjian Zuo et al. P22 used the scraper method to coat KB@Ir on the surface of the PP separator to modify the PP separator. Among them, the kB@Ir nanoparticles with a catalytic layer not only had a strong chemical reaction with polysulfides, but also It can promote the conversion of polysulfides, and the reduction of soluble polysulfides is called LiSz/LizS, thereby improving the battery efficiency. Kai Liu et al. sandwiched silica nanoparticles between two inert polymer separators without contact with active anode/cathode such as Li metal. Silica can consume lithium dendrites which can significantly improve the cycle life of the separator in the battery. Xian Wu et al. prepared Prussian blue (PB) modified celgard separator as a battery separator, PB is a material of MOF with high stability, and the unique open framework with large interstitial sites can ensure Li* migration, but hinders Migration of polysulfides and increase the Coulombic efficiency of the battery.

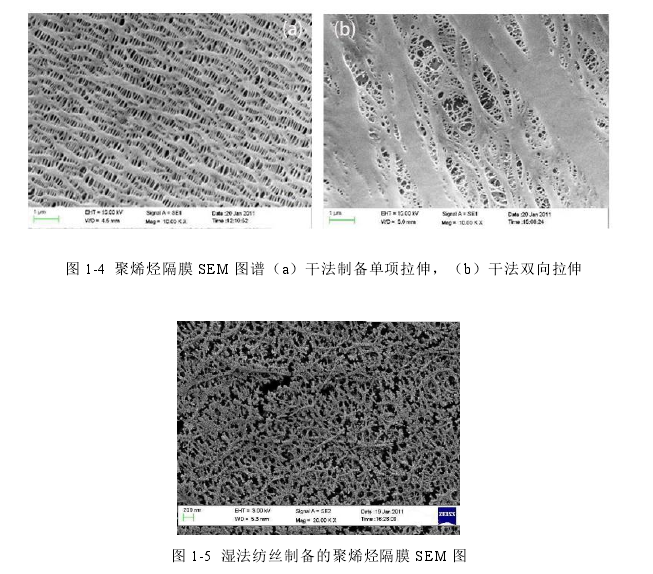

In addition to the drawdown blade method, there are also methods such as dry stretching and wet stretching to prepare polyolefin separators.