The water-based composite rock flake imitation granite coating has a wide range of applications, and can give buildings a grand and solemn aesthetic feeling. It is a stone imitation coating with an appearance and decorative effect similar to natural granite stone. It is suitable for architectural coatings that use colored composite rock flakes and stone particles as aggregates, synthetic resin emulsion as the main film-forming substance, and form a granite-effect coating on the surface of buildings through spraying and other construction processes. It is mainly used in buildings. , Decoration and protection of the outer surface.

Today we will introduce the regulations of HG/T 4344-2012 on water-based composite rock chip imitation granite coatings. Before testing, we need to understand the classification of water-based composite rock chip imitation granite coatings. We divide them into R type and P type according to their flexibility.

R type is a flexible water-based composite rock chip imitation granite coating, which is suitable for building surface finishing projects that require anti-cracking; P type is an ordinary water-based composite rock chip imitating granite coating, suitable for ordinary building surface finishing projects.

Item detection

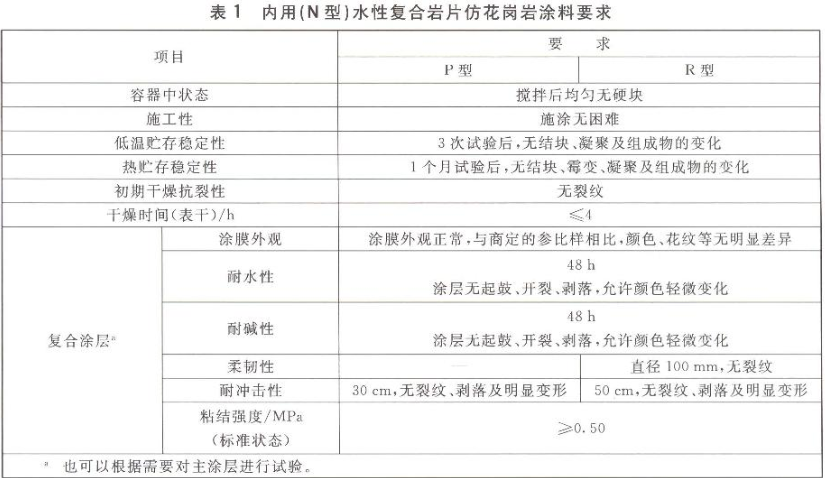

Performance testing requirements for internal use products

1. State in the container: First, we open the container, stir with a spatula or stir bar, and allow precipitation at the bottom of the container. If the R-type sample and the P-type sample are easy to mix evenly after stirring, it is rated as "uniform without lumps after stirring".

2. Constructability: If there is no difficulty in the construction process of R-type samples and P-type samples, it will be rated as "no barriers to application".

3. Low-temperature storage stability: put the R-type sample and P-type sample into a plastic or glass container of about 1L to a height of about 110 mm, seal it and put it in a low-temperature box at (-5±2)°C for 18 hours After taking it out, place it under the condition of (23±2)°C for 6h. After repeating the cycle operation 3 times, open the container cover, gently stir the internal sample, and observe the sample. If there is no agglomeration, agglomeration and change of composition, it is regarded as up to standard.

4. Thermal storage stability: put the R-type sample and P-type sample into a plastic or glass container of about 1L to a height of about 110mm. Put it in a constant temperature box at (50±2)°C after sealing it, take it out after 1 month, open the container cover, stir the internal sample gently and observe, if there is no agglomeration, mildew, condensation and composition changes ( Such as bleeding, dissolution of rock flakes, etc.), it is considered up to standard.

5. Initial drying crack resistance: Observe the changes of the R-type sample and the P-type sample in the dry state. If there is no crack, it is considered to be up to the standard.

6. Drying time: If the surface-drying time of the R-type sample and the P-type sample is ≦4h, it is regarded as up to standard.

7. Composite coating

a. Appearance of the coating film: Visually observe the R-type sample and the P-type sample under scattered sunlight. If the coating film is uniform, without sagging, blooming, pinholes, cracking and peeling, etc., it is rated as "" Appearance of the coating film is normal".

b. Water resistance: R-type samples and P-type samples are immersed in third-grade water for 48 hours. Take it out after the test, and gently blot the water on the attached plate with filter paper. After standing in the standard environment for 3 hours, observe the surface of the R-type sample and the P-type sample. If the coating has no coating film abnormalities such as swelling, cracking, and peeling, and a slight color change is allowed, it is considered to be up to the standard.

c. Alkali resistance: immerse R-type samples and P-type samples in saturated calcium hydroxide solution for 48 hours. Take it out after the test, use filter paper to gently blot the water on the surface of the attached board, and place it in a standard environment for 3 hours, observe the surface of the R-type sample and P-type sample, if the coating has no swelling, cracking, peeling, etc. Morbid phenomenon, allowing a slight change in color, is considered up to standard.

d. Flexibility: Cut 3 pieces of the R-type sample into a test piece with a size of 150mm×70mm. If there is no crack within the randomly selected 100mm sample range, it is considered to be up to the standard.

e. Impact resistance: In the test, if the P-type sample has no cracks, peeling and obvious deformation within the randomly selected 30mm sample range, and the R-type sample has no cracks, peeling and obvious deformation within the randomly selected 50mm sample range, then it is considered Up to standard.

f. Bonding strength: If the bonding strength of the R-type sample and the P-type sample is ≥0.50MPa under the standard state , it is considered to be up to the standard.

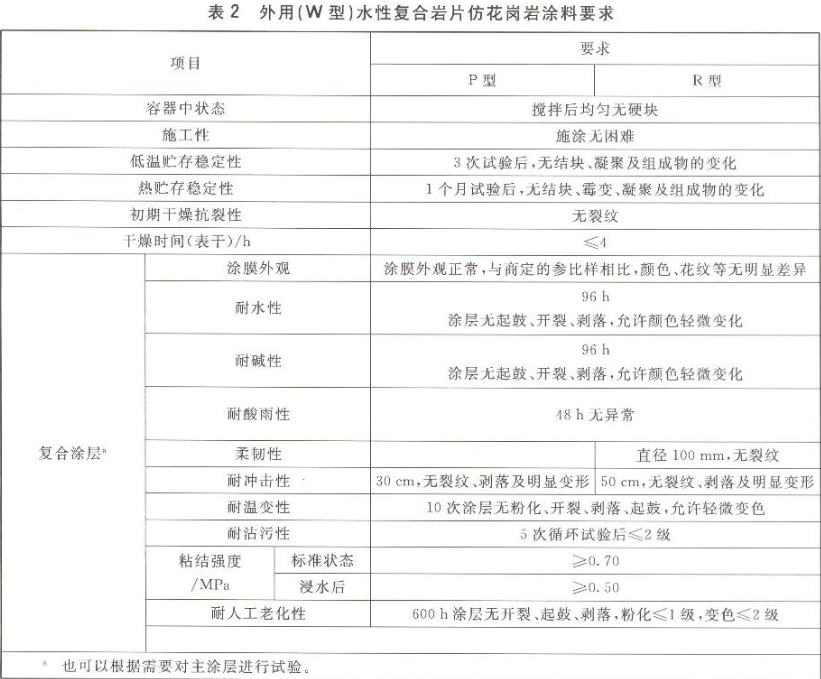

Performance testing requirements for external use products

1. State in the container: First, we open the container, stir with a spatula or stir bar, and allow precipitation at the bottom of the container. If the R-type sample and the P-type sample are easy to mix evenly after stirring, it is rated as "uniform without lumps after stirring".

2. Constructability: If there is no difficulty in the construction process of R-type samples and P-type samples, it will be rated as "no barriers to application".

3. Low-temperature storage stability: Put the R-type sample and P-type sample into a plastic or glass container of about 1L to a height of about 110mm, seal it and put it in a low-temperature box at (-5±2)°C for 18 hours. After taking it out, place it under the condition of (23±2)°C for 6h. After repeating the cycle operation 3 times, open the container cover, gently stir the internal sample, and observe the sample. If there is no agglomeration, agglomeration and change of composition, it is regarded as up to standard.

4. Thermal storage stability: put R-type samples and P-type samples into about 1L plastic or glass containers to a height of about 110 mm. Seal it and put it in a constant temperature box at (50±2)°C, take it out after 1 month, open the container cover, gently stir the internal sample and observe, if there is no agglomeration, mildew, condensation and composition changes ( Such as bleeding, dissolution of rock flakes, etc.), it is considered up to standard.

5. Initial drying crack resistance: Observe the changes of the R-type sample and the P-type sample in the dry state. If there is no crack, it is considered to be up to the standard.

6. Drying time: If the surface-drying time of the R-type sample and the P-type sample is ≦4h, it is regarded as up to standard.

7. Composite coating

a. Appearance of the coating film: Visually observe the R-type sample and the P-type sample under scattered sunlight. If the coating film is uniform, without sagging, blooming, pinholes, cracking and peeling, etc., it is rated as "" Appearance of the coating film is normal".

b. Water resistance: R-type samples and P-type samples are immersed in third-grade water for 96 hours. Take it out after the test, and gently blot the water on the attached plate with filter paper. After standing in the standard environment for 3 hours, observe the surface of the R-type sample and the P-type sample. If the coating has no coating film abnormalities such as swelling, cracking, and peeling, and a slight color change is allowed, it is considered to be up to the standard.

c. Alkali resistance: Soak R-type samples and P-type samples in saturated calcium hydroxide solution for 96 hours. Take it out after the test, use filter paper to gently blot the water on the surface of the attached board, and place it in a standard environment for 3 hours, observe the surface of the R-type sample and P-type sample, if the coating has no swelling, cracking, peeling, etc. Morbid phenomenon, allowing a slight change in color, is considered up to standard.

d. Acid rain resistance: Soak three R-type samples and P-type three samples in the prepared simulated acid rain solution for 48 hours. Take it out after the test, use filter paper to gently blot the water on the surface of the attached plate, and place it in the standard environment for 3 hours, observe the surface of the R-type sample and the P-type sample, if there are three samples in each of the R-type and P-type samples If there is no bubbling, cracking, peeling, powder falling, obvious discoloration, obvious loss of gloss and other coating film pathological phenomena, it is rated as "no abnormality".

e. Flexibility: Cut 3 pieces of the R-type sample into a test piece with a size of 150mm×70mm. If there is no crack within the randomly selected 100mm sample range, it is considered to be up to standard.

f. Impact resistance: In the test, if the P-type sample has no cracks, peeling and obvious deformation within the randomly selected 30mm sample range, and the R-type sample has no cracks, peeling and obvious deformation within the randomly selected 50mm sample range, then it is considered Up to standard.

g. Resistance to temperature change: After spraying the R-type sample and the P-type sample for 10 times, let it stand for observation. If there is no pulverization, cracking, peeling, and bulging, and slight discoloration is allowed, it is considered to be up to the standard.

h. Contamination resistance: The R-type sample and the P-type sample are subjected to 5 cycle tests, and if the result is that the stain resistance is ≤ 2, it is considered to be up to the standard.

i. Bonding strength: If the bonding strength of R-type samples and P-type samples is ≥0.70MPa under the standard state, and the bonding strength after soaking in water is ≥0.50MPa, it is regarded as up to the standard.

j. Artificial aging resistance: put the R-type sample and P-type sample in the test environment for 600 hours, if the result shows that the coating has no cracking, swelling, peeling, powdering ≤ level 1, and discoloration ≤ level 2, it is considered up to the standard.