Color offset printing paper is widely used in offset printing of newspapers, books and periodicals due to its water resistance and tensile properties. Today we will introduce the testing requirements for color offset printing paper stipulated in the QB/T 2693-2005 standard. Before testing, we need to divide the color offset printing paper into high-quality products and qualified products according to the quality, and into flat paper and roll paper according to the style.

Item detection

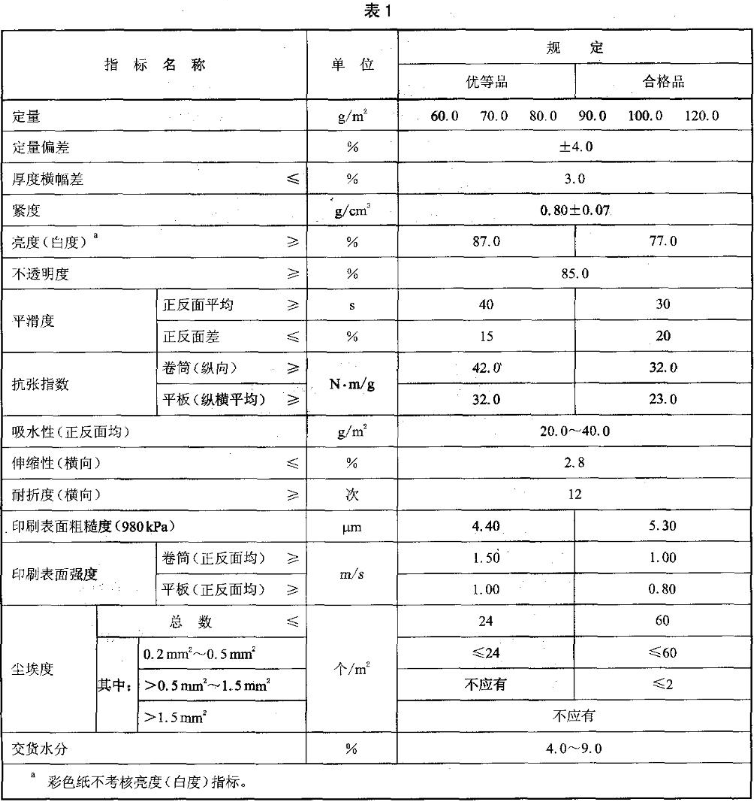

1. Quantitative and quantitative deviation: the magnitude of excellent products and qualified products is divided into six levels: 60.0g/m², 70.0g/m², 80.0g/m², 90.0g/m², 100.0g/m², 120.0g/m² . Its quantitative deviation needs to be within the range of ± 4.0% to meet the standard.

2. Difference in thickness and banner: superior products and qualified products must be ≤3.0% to be considered up to standard.

3. Tightness: The superior and qualified products must be within the range of 0.80g/m³±0.07g/m³ to be considered up to the standard.

4. Brightness (whiteness): ≥87.0% for high-quality products and ≥77.0% for qualified products.

5. Opacity: ≥ 85.0% for high-quality products and qualified products to be considered up to the standard.

6. Smoothness: In the average of the front and back sides, the excellent product needs to be ≥ 40s, and the qualified product needs to be ≥ 30s; in the difference between the front and back sides, the high-quality product needs to be ≤ 15%, and the qualified product needs to be ≤ 20%, so as to meet the standard.

7. Tensile index: the high-quality products of roll longitudinal paper need to be ≥42.0N m/g, and the qualified products must be ≥32.0N m/g; The product needs to be ≥ 23.0N·m/g to be considered up to standard.

8. Water absorption: Both the front and back of superior products and qualified products must be within the range of 20.0g/m²~40.0g/m² to be considered up to the standard.

9. Scalability: The horizontal scalability of superior and qualified products must be ≤2.8% to meet the standard.

10. Folding resistance: The horizontal folding resistance of superior products and qualified products must be ≥12 times to be considered up to the standard.

11. Roughness of the printing surface: Use a cushion, clamp the sample pressure 980kPa, if the test result is 4.40kPa for the superior product, and 5.30kPa for the qualified product, then it is considered to be up to the standard.

12. Printing surface strength: the high-quality products of the front and back reels need to be ≥1.20m/s, and the qualified products must be ≥1.00m/s; It's up to the mark.

13. Dirt Count: The total Dirt Count of superior products must be ≤ 24mm², and the total Dirt Count of qualified products must be ≤ 60mm². Among them, in the range of 0.2mm²~0.5mm², superior products need to be ≤24mm², and qualified products need to be ≤60mm²; in the range of >0.5mm²~1.5mm², superior products should not detect 1mm², and qualified products need to be ≤2mm²; in the range of >1.5mm² Within the range, both superior products and qualified products should not detect 1mm², so as to meet the standard.

14. Moisture content in delivery: superior products and qualified products must be in the range of 4.0%~9.0% to be regarded as up to standard.