The raw material of gravure printing paper is bleached chemical wood pulp, and some bleached cotton pulp is also mixed. It is printing paper for gravure printing. It is suitable for monochrome and color printing pictorials, art pictures, illustrations, etc. paper.

Today we will introduce the testing requirements for gravure printing paper stipulated in the QB/T 2249-1996 standard. Before testing, we need to divide the gravure printing paper into flat paper and roll paper according to the finished products.

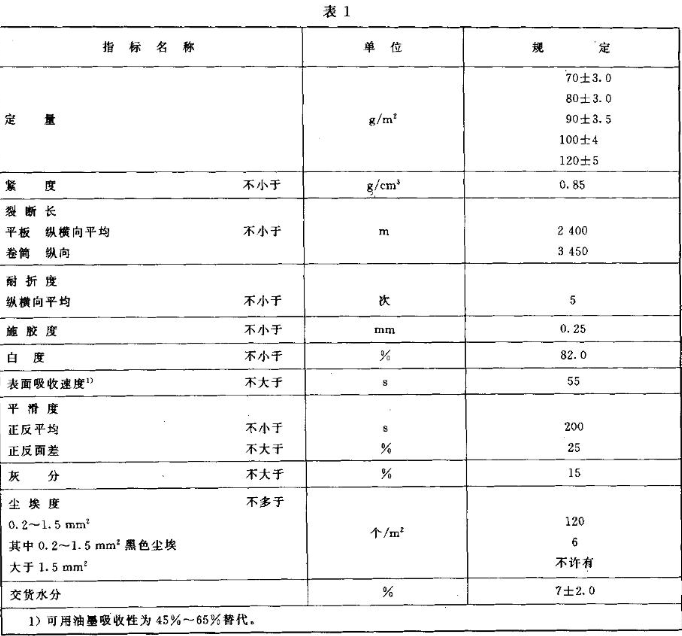

Item detection

1. Quantitative: The magnitude of flat paper and web paper is divided into 70±3.0g/m², 80.0±3.0g/m², 90.0±3.5g/m², 100.0±4.0g/m², 120.0±5.0g/m² five levels.

2. Tightness: flat paper and roll paper must be within the range of ≥0.85m³ to meet the standard.

3. Flat vertical and horizontal average and reel longitudinal average: the flat vertical and horizontal average of flat paper and roll paper needs to be ≥ 2400m, and the roll vertical needs to be ≥ 3450 to meet the standard.

4. Folding endurance: the vertical and horizontal average folding endurance of flat paper and roll paper must be ≥ 5 times before it can be considered up to the standard.

5. Sizing degree: flat paper and roll paper need to be ≥0.25mm to meet the standard.

6. Whiteness: flat paper and roll paper must be ≥82.0% to meet the standard.

7. Surface absorption speed: flat paper and roll paper need to be ≤55s to meet the standard.

8. Smoothness: The average smoothness of the front and back of flat paper and roll paper must be ≥ 200s, and the difference between the front and back sides must be ≤ 25%, so as to meet the standard.

9. Ash content: Flat paper and roll paper need to be ≤15% to meet the standard.

10. Dirt Count: within the range of 0.2mm²~0.5mm² for flat paper and roll paper, ≤120 pieces/m² is required; within the range of 0.2~1.5mm² black dust, ≤6 pieces/m² is required; no >1.5mm² range is allowed If it is inside, it will be regarded as reaching the standard.

11. Delivery moisture: flat paper and roll paper must be within the range of 7±2.0 to meet the standard.