ATO slurry can be dispersed by ball mill dispersion, ultrasonic dispersion, and high-speed dispersion. The three methods have their own advantages and disadvantages. details as follows:

(1) Dispersion by ball milling

Ball mill dispersion : The dispersed slurry has good stability and uniform particle distribution. It can disperse a variety of samples at one time, and obtain the dispersion effect of different formulas; but it takes a long time, and it is more suitable for use under fine-tuning of the formula to adjust the slurry. Adjust the proportion of solvent, ATO powder, etc. in the The grinding time of the ball mill is generally controlled within 12-16 hours.

(2) Ultrasonic dispersion

Ultrasonic dispersion: Ultrasonic dispersion is the fastest dispersion method among the three dispersion methods. It can quickly disperse the ATO slurry, but the amount of slurry dispersed at one time is small, and it needs better control of the dispersion time. The temperature is controlled within the range of 20-40°C to prevent the slurry from overflowing. This dispersion method is more suitable for the initial test of small doses of slurry in the early preparation process of slurry. The grinding time of ultrasonic dispersion is generally controlled within 10-20 minutes.

(3) High-speed dispersion

High-speed dispersion : The high-speed dispersion Grinder can disperse the slurry evenly in a short period of time, which is a relatively fast and effective experimental method. However, during the operation process, the volume of the slurry required by the container is generally 0.3-0.4L, which is more suitable for examining the mid-term and late-stage blending effect of the slurry after the formula is determined, and is not suitable for the early-stage blending of the slurry, otherwise Slurry waste and continuous cleaning of the Grinder, injection of slurry, etc. occur. The grinding time of high-speed dispersion is generally controlled within 120-180 minutes.

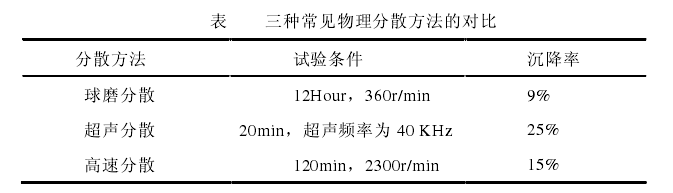

Taking the quality of α dispersant/mass of ATO powder=16% as an example, the three dispersion methods of ball mill dispersion, ultrasonic dispersion and high-speed dispersion are studied and analyzed. The ball mill dispersion time is 12 hours, the rotating speed is 360r/min, and the sedimentation rate obtained is 9%; the ultrasonic dispersion time is 20min, the ultrasonic frequency is 40KHz, and the sedimentation rate is 25%; the high-speed shear dispersion time is 120min, and the rotational speed is 230Or/min. The settlement rate is 15%. It can be seen from Table 2-4 that the time of ball mill dispersion is longer, but the stability of the dispersed slurry is better; the time of ultrasonic dispersion is the shortest, and the efficiency is the highest, but its dispersion effect is very unsatisfactory among the three; high speed The dispersing effect of dispersion is better, and the time is shorter, but only one kind of slurry can be dispersed at a time, which does not meet the requirements of large-scale multi-formulation experiments, and the overall efficiency is not high.