Anti-corrosion coatings for underwater production systems are anti-corrosion coatings suitable for subsea manifold terminals, jumper pipes, underwater wellheads, etc. Today we will introduce the provisions of GB/T 34677-2017 on anti-corrosion coatings for underwater production systems.

Item detection

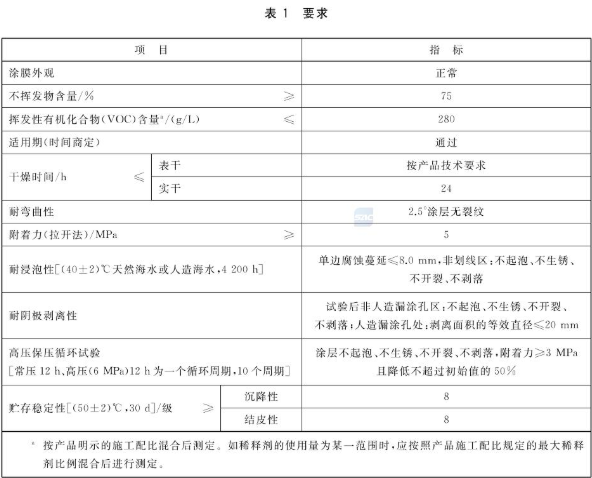

1. Appearance of the paint film: If the paint film of the sample is uniform, without sagging, blooming, cracks, shrinkage cavities, particles, etc., it can be rated as "normal".

2. Non-volatile matter content: if the sample is ≥75%, it is regarded as up to standard.

3. Volatile organic compound content: if the sample is ≤280g/L, it is regarded as up to standard.

4. Appropriate period: It is determined by the testing parties according to the actual situation.

5. Drying time: The surface dryness of the sample is according to the technical requirements of the product, and the hard drying ≤ 24h is considered to be up to the standard.

6. Bending resistance: Bend the sample to 2.5°, take a certain range for observation, if the coating has no cracks, it is considered up to the standard.

7. Adhesion: A test column with a diameter of 20 mm is used, and the upper and lower test columns are concentrically connected with the test plate for the test. If the sample ≥ 5MPa, it is regarded as up to standard.

8. Immersion resistance: Soak the sample in natural seawater or artificial seawater at (40±20)°C for 4200 hours, take out the sample plate for observation after the test, if the unilateral corrosion spread ≤ 8.0mm, there is no blistering in the non-marked area, If there are pathological phenomena of coating film such as rusting, cracking and peeling, it is considered to be up to the standard.

9. Cathodic disbonding resistance: After the test, take out the sample plate for observation. If there is no coating film pathology such as blistering, rust, cracking and peeling in the non-artificial leak-coating hole area; the equivalent diameter of the peeling area in the artificial leak-coating hole area is ≤ 20mm is considered up to standard.

10. High-pressure holding cycle test: 12 hours at normal pressure and 12 hours at high pressure (6MPa) are used as a cycle, and 10 cycle tests are carried out. After the test, take out the sample plate for observation. If there is no blistering, rust, cracking and peeling off of the coating If the coating film is pathological, if the adhesion force is ≥3MPa and the reduction does not exceed 50% of the initial value, then it is considered to be up to the standard.

11. Storage stability: Store at (50±2)°C for 30 days, take it out and place at (23±2)°C for 3 hours, if the crusting and sedimentation properties are both ≥8 grades, it is considered up to standard.