GB/T 22374—2018适用于涂装在水泥砂浆、混凝土等基面上,对地面起装饰、保护作用以及具有特殊功能(防静电性、防滑性等)要求的合成树脂基和聚合物水泥复合地坪涂装材料。今天我们就来介绍一下此标准对聚合物水泥符合地坪涂装面涂的规定。

在介绍之前我们先要了解它的分类,我们According to聚合物水泥复合型地坪涂装材料的成膜机理分为:JJ型,有机交联反应型聚合物水泥复合地坪涂装材料和FJ型,非有机交联反应型聚合物水泥复合地坪涂装材料。

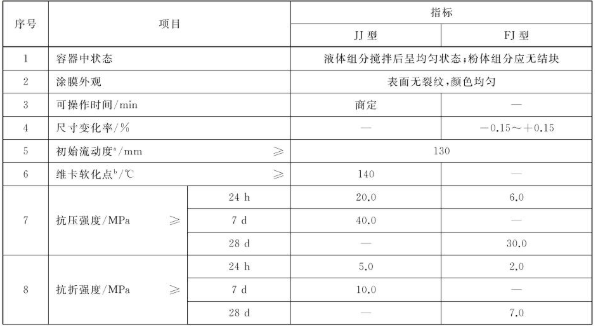

项目检测

1、在容器中状态:若JJ型和FJ型搅拌后呈均匀状态,无硬块,则算达标。

2、涂膜外观:目视法观察涂膜,若表面平整,无显著缩孔、浮色等涂膜病态现象,则评定为“正常”。

3、可操作时间:由测验双方按实际情况自行决定参考参数。

4、尺寸变化率:FJ型需在-0.15~+0.15范围内,方算达标。

5、初始流动度:若样品≥130mm,则算达标。

6、维卡软化点:若JJ型样品≥140℃,则算达标。

7、抗压强度:若JJ型样品在24h内≥20.0MPa、7d内≥40.0MPa;FJ型在24h内≥6.0MPa、28d内≥30.0MPa,则算达标。

8、抗折强度:若JJ型样品在24h内≥5.0MPa、7d内≥10.0MPa;FJ型在24h内≥2.0MPa、28d内≥7.0MPa,则算达标。

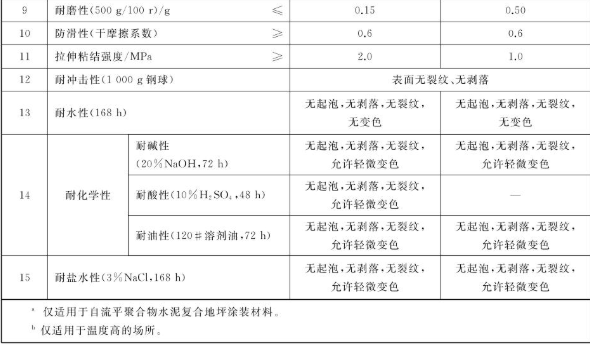

9、耐磨性:在500g/100r的测试中,若JJ型样品≤0.150g;FJ型样品≤0.50g,则算达标。

10、防滑性:若JJ型样品的干摩擦系数≥0.6,FJ型样品的干摩擦系数≥0.6则算达标。

11、拉伸粘结强度:JJ型样品≥2.0MPa;FJ型样品≥1.0MPa,方算达标。

12、耐冲击性:在1000g钢球的测试要求下,若涂膜无裂纹剥落等涂膜病态现象,则算达标。

13、耐水性:浸水168h,若无起泡剥落等涂膜病态现象,则算达标。

14、耐化学性

耐碱性:浸泡在20%的NaOH溶液中72h,若无起泡剥落等涂膜病态现象,允许轻微变色,则算达标。

Acid resistance: Soak the JJ type sample in 10% H2SO4 solution for 48 hours, if there is no abnormal phenomenon of coating film such as blistering and peeling, and slight discoloration is allowed, it is considered to be up to the standard.

Oil resistance: soaked in No. 120 solvent oil for 72 hours, if there is no abnormal phenomenon of coating film such as blistering and peeling, and slight discoloration is allowed, it is considered to be up to the standard.

15. Salt water resistance: soaked in 3% NaCI solution for 168 hours, if there is no abnormal phenomenon of coating film such as blistering and peeling, and slight discoloration is allowed, it is considered to be up to the standard.

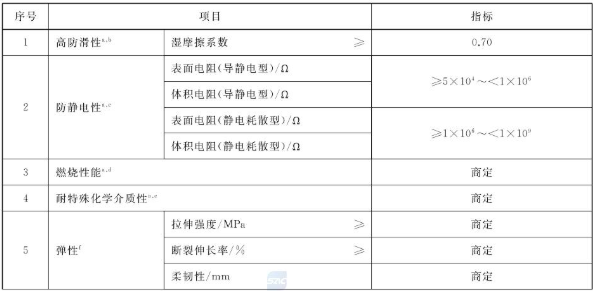

Special performance requirements for top coat or coating system of floor coating materials

1. High skid resistance: wet friction coefficient ≥ 0.70

2. Anti-static property: the surface resistance and volume resistance of the conductive type are ≥5*10^4Ω~1*10^6Ω

3. Combustion performance: The reference parameters are determined by both parties of the test according to the actual situation.

4. Resistance to special chemical media: The reference parameters are determined by both parties of the test according to the actual situation.

5. Elasticity: The reference parameters are determined by both parties of the test according to the actual situation.