GB/T 25261-2018 is applicable to uniform colors made of resins, pigments and fillers, additives, functional materials, etc. Today we will introduce the provisions of this standard for painting in building reflective insulation.

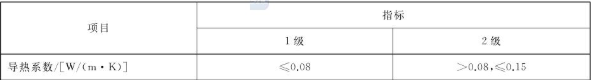

Before introducing it, we must first understand its classification. We divide it into grade 1 and grade 2 according to the heat insulation effect; according to the basic performance, it is divided into ordinary type (P type) and elastic type (T type).

Item detection

functional requirements

Thermal conductivity: ≤0.08m*k for class 1 samples, >0.08m*k for class 2 samples, ≤0.15m*k

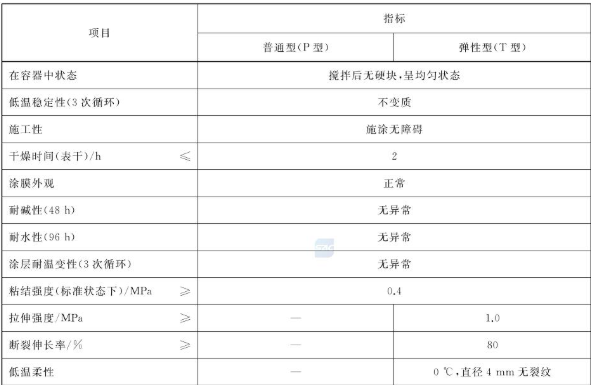

Basic performance requirements

1. State in the container: If the P-type and T-type are in a uniform state after stirring, and there is no hard lump, it is considered to be up to standard.

2. Low temperature stability: carry out three cycle tests, if the result is no deterioration, it is regarded as up to standard.

3. Constructability: If the result is "no obstacle for brushing", it is regarded as up to standard.

4. Drying time: if the surface of the sample is dry ≤ 2 hours, it is considered up to the standard.

5. Appearance of the coating film: observe the coating film visually. If the surface is smooth and there is no significant shrinkage cavity, cracking and other coating film pathological phenomena, it is rated as "normal".

6. Alkali resistance: Soak in the test solution for 48 hours, if there is no abnormal phenomenon of coating film such as foaming and falling powder, and slight discoloration is allowed, it is considered to meet the standard.

7. Water resistance: immersion in water for 96 hours, if there is no abnormal phenomenon of coating film such as foaming and falling powder, it is considered to meet the standard.

8. Coating resistance to temperature denaturation: carry out three cycle tests, if there is no abnormality in the result, it is regarded as up to standard.

9. Adhesive strength: if the sample is ≥0.4MPa, it is regarded as up to standard.

10. Tensile strength: If the T type is ≥1.0MPa, it is considered to be up to standard.

11. Elongation at break: If the T type is ≥ 80%, it is regarded as up to standard.

12. Low-temperature flexibility: If the T-shaped result is 0°C and the diameter is 4mm without cracks, it is considered up to the standard.