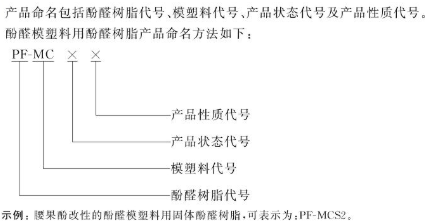

Phenolic resins for phenolic molding compounds are synthesized from phenols and aldehydes as main raw materials. According to the state of the product, it is divided into two types: solid and liquid, which are represented by S and L respectively. Divided into six categories according to product properties: pure resin (code 1), cardanol modified resin (code 2), melamine modified resin (code 3), polyvinyl butyral (PVB) modified resin (code 4) , Aniline modified resin (code 5), other modified resins (code 6).

Today I will introduce what conditions should be met in the performance testing of phenolic resins for phenolic molding compounds under the provisions of GB/T30772-2014. The product needs to be named before testing to prevent confusion. See below.

Item detection

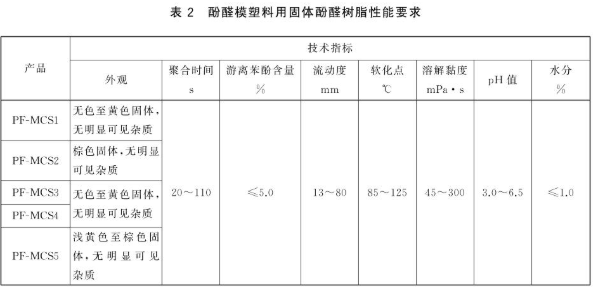

Performance requirements of solid phenolic resin for phenolic molding

1. Appearance: Codes 1, 3, and 4 should be in the form of colorless to yellow solids without obvious impurities; code 2 should be in the form of brown solids without obvious impurities; code 5 should be in the form of light yellow to brown solids without obvious impurities Visible impurities;

2. The polymerization time is 20s~11s.

3. Free phenol content ≤ 5.0%.

4. The swimming degree is 13mm~80mm.

5. The softening point is 85℃~125℃.

6. The solution viscosity is 45MPa*s~300MPa*s.

7. The pH value is 3.0~6.5.

8. Moisture content ≤1.0%.

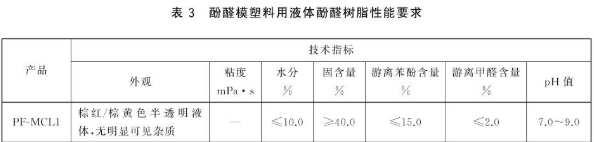

Performance requirements of liquid phenolic resins for phenolic molding compounds

Code 6: The appearance should be brown-red/brown-yellow translucent liquid, without obvious visible impurities; moisture ≤ 10.0%; solid content ≥ 40.0%; free phenol content ≤ 15.0%; free formaldehyde content ≤ 2.0%; pH value 7.0 ~9.0.