Paint Testing – Paint is a solution mixture of pigments, solvents, resins and additives. The pigment is the color, the solvent is the vehicle that makes it liquid and evaporates when the paint dries, the resin is the binder or glue, and the additives have specific performance characteristics.

Coating Testing - A coating is a thin layer covering on a substance or product, applied or deposited on the surface of any product, primarily to improve its properties and to form a protective barrier against corrosion and deterioration of its surface.

In various industries such as the infrastructure and construction industry, the automotive industry, "paint" is usually an industrial two-pack paint, and "coating" is a word used to define a product to which a layer of paint, polymer or metal coating is applied for protection .

In order to verify and check the characteristic and functional parameters of coatings and coating testing focused on the properties required therein, some mechanical and physical tests can be administered to obtain specific data and information, such as verification of coating thickness and ongoing processing.

There are many markets for paint testing and coatings, from home builders to manufacturers. In many other cases, consumers own the specs for reasons ranging from aesthetics to safety. The paint and coatings industry applies a wide range of tools, methods and techniques to test quality control

Coatings are used to protect manufacturing steel plants such as offshore rigs, bridges and other structures from rust and ensure that as long as the product is exposed to a variety of harsh environmental conditions. To ensure the performance of the coating, the coating is tested. Physical tests such as scratch and impact tests can be performed.

Paint testing is required to protect various structures from the harsh effects of sunlight and water.

Ultra-aesthetic for added beauty and impact.

ENHANCED PROTECTION Mother nature can be harsh at times as the sun, rain, fire, wind and snow can severely damage your home.

Extended Life, A good coat helps extend the shelf life of your home or any product.

Coating testing is required because:

They provide safety by making the surface of the product non-stick or sticky.

They protect against corrosion as, over time, rust and other mechanically corrosive debris can develop.

They provide protection by maintaining luster, hardness and other properties for a long time.

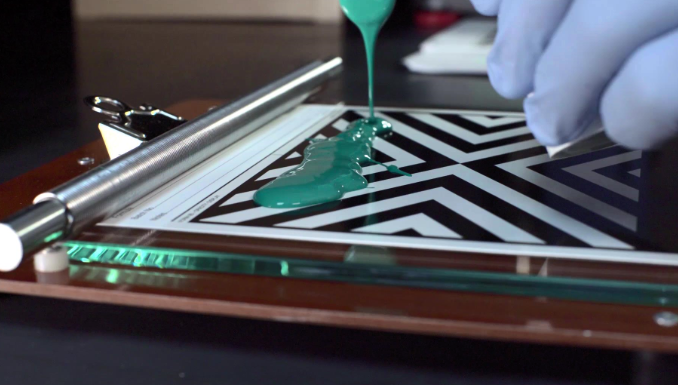

In the paint industry, the importance of viscosity as a measure of its thickness cannot be overemphasized, as viscosity determines whether a paint needs to be applied with a sprayer, roller, brush or more high-tech tools. It also takes knowing to apply paint evenly and correctly on uneven surfaces. Viscosity is measured and tested using various viscometers and is usually measured by the time and speed with which the paint slides and moves.

Specific gravity is a measure of the density of paint, usually expressed in weight per gallon.

Test for Oil and Dirt Contamination To determine the presence of grease, dirt, oil contamination, rub a spot back and forth on the surface with a dry cotton pad ten times. Black marks on cotton pads show oil and dirt.

Abrasion resistance testing helps to determine the coating's ability to resist degradation due to mechanical abrasion caused by hard and rough objects.

Alkali resistance test of paint to determine the temperature at which the paint resists reaction with alkaline substances such as gypsum, lime, cement, etc.

Cass testing, to determine the corrosion properties of metals or other products, uses salt spray testing. Chemical analysis of paints and coatings to check if the product reacts to any chemicals.

Accelerated aging of the paint provides a relative measure of how long it will last outdoors compared to other existing formulations.

Pretreatment tests are performed to determine the behavior and response of paints and other types of coatings when exposed to various humidity conditions, at temperatures defined as required by the product or coating specification.

Water resistance testing, like water, can cause the coating to degrade, so check how well the coating resists water.