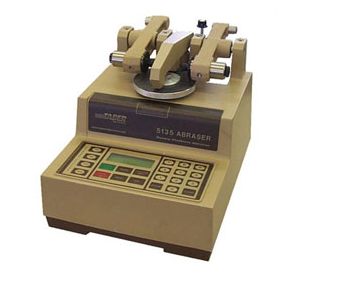

Taber abrasion is a method used to determine the ability of a material to withstand abrasion. Taber abrasion is evaluated using the so-called Taber Abrasion Test or Taber Abraser. Taber wear uses two grinding wheels under which the material being evaluated is rotated for a given time and under a given load.

Taber abrasion testing is performed on coated materials because if the coating is allowed to wear, the substrate will be exposed to the environment and cause premature failure due to corrosion.

Taberwear

Taber Abrasion is manufactured by Taber Corporation and it has become one of the most prominent forms of testing materials for abrasion resistance. For Taber abrasion testing, a sample of material is loaded into a Taber abrasion machine. The Taber Abraser has two grinding wheels which are lowered onto the material for a certain period of time under a constant load. After the Taber Abraser has completed its cycle, the tested material is evaluated by determining the amount of weight loss as a function of the test time and applied load.

Taber wear can be evaluated for many different materials. Taber abrasion can be used to evaluate base metals, ceramics, polymers and fabrics. Taber wear tests are often performed on coated materials.

An example is buried pipes. The pipe's coating is tested to ensure it can withstand the abrasion caused by soil and other ground materials moving around it.