There are two key points in the selection of the automatic film coating machine, one is the nature of the substrate and the sample, and the other is the thickness of the coating film. In addition, consider other functional requirements. Polyimide is a polymer material with high heat resistance. It is used as a substrate to make a scraping film. Simply speaking, it is actually an emulsion coating on a polymer film.

As a film substrate, there is no doubt that the vacuum adsorption function is required, unless it is a very hard film, but polyimide is generally a relatively flexible film substrate, so it must be equipped with a vacuum adsorption function. In addition, SEP emulsion is a sample with low viscosity, so it can be scraped with a wire stick and a scraper. In fact, due to the various thicknesses of the scraping coating, it can be equipped with a wire rod + scraper integrated film coating machine model. Of course, the NBCHAO film coating machine can also be equipped with a manual scraping coating Applicator, which is not necessarily an integrated one.

In addition, in the coating experiment of polymer materials, it is often necessary to dry and cure the film after scraping the film. Generally, there are two options, one is to put the film on the oven for drying, and the other is to dry the film through the coating. The built-in heating and drying function of the machine can cure quickly.

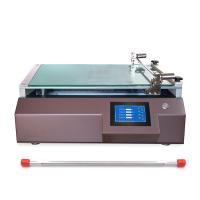

To sum up the above case analysis, the four-in-one automatic film coating machine is an optimal solution for the type selection requirements of the coating film, which can meet the various needs of high-low film thickness. In addition, a three-in-one coating Tester with wire rod + heating + vacuum adsorption function can also be used, which is suitable for low-viscosity coating films. The detailed plan is as follows:

| Membrane Proofing- Membrane | |

| Domestic TBJ-X4 vacuum adsorption wire rod heating integrated coating testing machine |

| Specification parameters: coating speed 2~200mm/s, coating width 300*400mm (coating length 0-400mm can be set arbitrarily), coating speed digital display, different speeds, vacuum adsorption size 300*400mm (customizable) , Vacuum hole diameter Φ1.2mm, vacuum hole distance 20*20mm, coating rod specification accuracy 0.001mm, effective coating width 300mm (determine the coating thickness according to the wire rod model), host power supply 220V 50HZ, external dimensions 630*410*520mm , net weight 65KG, speed control stepless speed change, base plate material aluminum alloy, heating temperature range RT+~200°C, temperature uniformity temperature ±3°C, Vacuum Pump size 380*180*280mm, optional accessories leakage tank, substrate fixing fixture , fine-tuning level height support foot device, glass plate, silicone pad and weight (for the application of uneven thickness of coating substrate), coating film width control baffle, customizable function jet system device, UV solid containing device, automatic adding ink system | |

| Domestic TBJ-X3-XB vacuum adsorption wire rod scraper heating integrated coating testing machine |

| Specification parameters: scraper coating accuracy ±0.003mm, coating thickness range 0~10mm scraper can be raised and lowered, coating rate 2~200mm/s, coating width 300*400mm (coating length 0-400mm can be set arbitrarily), coating Speed digital display, different speeds, vacuum adsorption size 300*400mm (customizable), vacuum hole diameter Φ1.2mm, vacuum hole distance 20*20mm, scraper length, coating rod specification 1 domestic wire rod + 1 rod, the accuracy is as high as 1μm imported wire rod, effective coating width 300mm (coating thickness is determined according to the type of wire rod), host power supply 220V 50HZ, external dimension 630*410*520mm, net weight 65KG, speed control infinitely variable speed, base plate material aluminum alloy, heating Temperature range RT+~200°C, temperature uniformity temperature ±3°C, power 1500W, Vacuum Pump size 380*180*280mm, optional accessories leakage tank, substrate fixing fixture, fine-tuning leveling height support leg device, glass plate, silicone pad And weights (for the application of uneven thickness of coating substrates), coating film width control baffle, customizable functional jet system device, UV solid containing device, automatic ink filling system | |

The above are two kinds of coating scheme equipment, for reference only, please consult Beichao Technology for details.