Since nearly every paint formulation needs to provide a specification for adhesion, it's no surprise that a critical number of routine measurements have been established in the quality inspection arena. This is true for cross-hatch testing, the paint technician's choice when adhesion needs to be assessed. However, the pull-off method is increasingly used to assist the cross-cut test.

Both methods have been the subject of national standardization. However, differences in national documentation are not important and it is relatively easy to develop international standards to ensure that these basic tests can be performed in a uniform manner.

Cross-cut test

The International Organization for Standardization (ISO) specifies the scope and procedures for practical and instructive methods to understand the adhesion of a coating by cutting a lattice pattern through the film, through the film, and into the substrate. Various cutting tools can be used for this purpose either manually or mechanically. A good choice is a multi-knife cutting tool, consisting of a set of six "knives" spaced 1 or 2 mm apart to produce a uniform pattern.

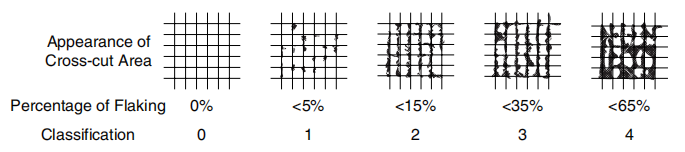

The test results were evaluated according to the scheme shown in the figure. Classification is based on an estimate of the number of paint flakes detached from the substrate. If in doubt about the actual shedding rate, brush off loose parts or tape them off.

The judgment of the degree of adhesion does not have to be based on the entire six-step classification. ISO proposes a standard that considers testing for "go-no-go" statements. In this case, class "O" would indicate perfect adhesion, while class "2", or even class "1", should be interpreted as an objectionable result. All higher-level coatings signal, although differentiated, that steps need to be taken to improve coating adhesion.

Grading principle of paint film adhesion in cross-cut test

Quantitative Determination Method of Adhesive Strength

stretching method

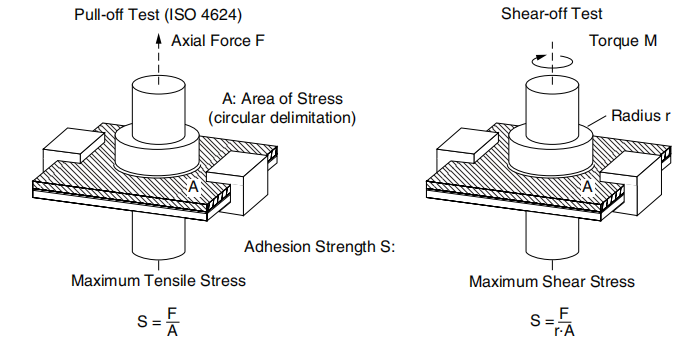

The typical stress distribution at the interface, caused by loads acting mainly on the contact surface normal or parallel to it, has been used as the basis for the relevant test method (Fig. 6.4). The pull-off method is currently the most widely used surgical method and has been standardized internationally. In preparation for the test, studs, usually made of steel, are bonded to the paint and subjected to axial tension until the paint film comes off. The result, the adhesion strength, is the maximum possible tensile stress at the interface.

However, if a torque is applied on the shaft of the stud, the process of separation reveals the maximum shear stress that can be reached at the interface, thus also leading to a characteristic measure of adhesion.

Adhesion strength values from either method proved to be of the same order. But in the case of adhesive failure, the result tends to be obtained by the principle of moment, and the result of adhesive failure is lower .

However, the accuracy of the tests, and the definition of their mechanical principles, must not lead to the idea that the values obtained in this way can be considered as material constants of the bonded components. Instead, there is the additional influence of several parameters, such as temperature, deformation rate, and even the shape and size of the stud.

Equally important is the stiffness of the test piece and the possibility to fix it for the measurement. As shown in the figure, for coatings on non-deformable substrates, the use of either clamp at the edge of the support near the attachment stud is fastening the test piece. the appropriate method. However, for flexible substrates such as plastic or leather, the sandwich principle is suggested. Since the adhesive is used to securely fasten the stud in the test area, it is necessary to discuss which type of adhesive is suitable, especially with regard to avoiding any negative effects of using it.

Generally, solvent-free epoxy adhesives cured with polyamines, or fast-hardening cyanoacrylates, are used for this purpose. To ensure reliability of results, the components of the adhesive must not interact with the coating in such a way as to cause full swelling. In terms of bond strength between adhesive and coating, it is beneficial that the coating only penetrates to the topmost layer. There are a variety of adhesives on the market and it should be possible to find a more suitable type.