Especially in order to determine the stone chip resistance of coatings that should provide effective protection of metal substrates from corrosion, the adhesion value at the interface is the main concern. By hitting the test piece with a steel ball, the situation encountered in practice can be replicated, but only under slightly satisfactory conditions. The force transmission through the film is approximately equal to the static load case; that is, it is calculated almost the same as for the indentation test.

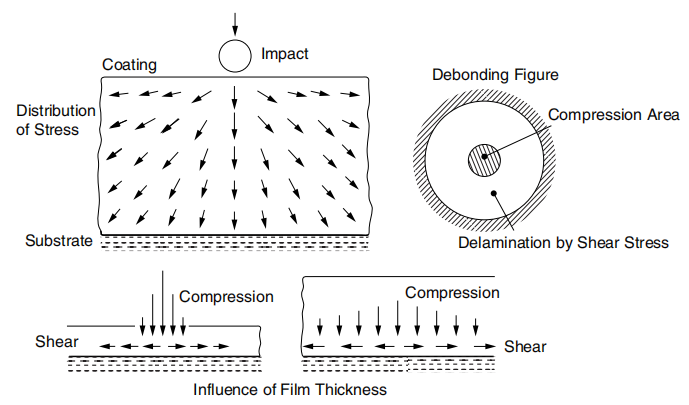

The graph is based on the adhesion information of the circular peel graph generated by the impact load of the paint film

Thus, in the disbond zone, two types of stress are active: negative tensile stress (i.e., compressive stress) in the center of the circular disbond zone, and, more importantly, shear stress in the annual zone. The size of the disbonded area, primarily the largest diameter, can be used to measure adhesion at the interface, and it is convenient to measure adhesion in terms of diameter or (better yet) the area of the disbonded area. Therefore, the absolute value of the adhesion force indicative of a low level of adhesion at an extended separation site can be calculated, at least in principle, but some additional parameters need to be considered.

The first is the significant effect of film thickness. For thin films, the separation zone is more concentrated near the impact axis. In areas where the coating is thicker, under the same test conditions, the area affected by the stress is larger, resulting in delamination. The details of this relationship are readily understood based on a particular scheme valid for the internal stress distribution throughout the film. The other parameters of the bond strength calculation are related to the impact of the steel ball.

Its mass, diameter and velocity -- before and after the impact -- need to be known, as well as the (usually short) duration of the impact, during which energy is transferred into the membrane.