Ⅰ.Principle of Automatic Film Applicator

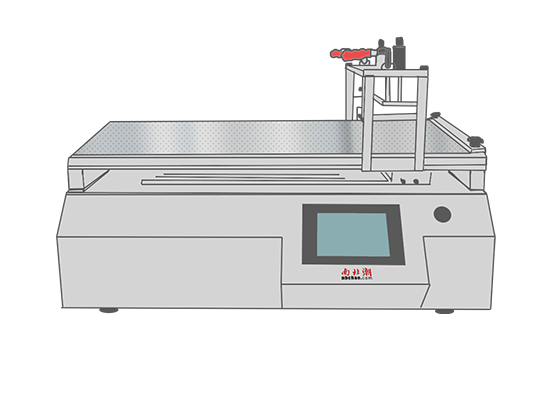

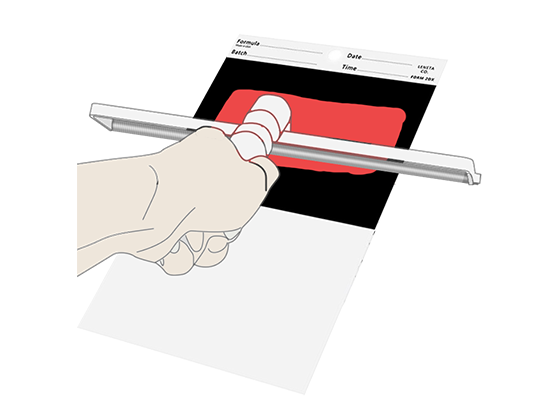

Automatic Film Applicator is a film device that assists technicians in accurate Moulding. Simulates manual operation, providing a film environment with more uniform force and constant speed. Generally matched with Applicator and Mayer Rods to control film thickness.

Automatic Film Applicator itself does not control the film thickness, determined by the film blade/bar.

Ⅱ.Application of Automatic Film Applicator

A. Research on coating materials

Laboratory studies will use a compact filmmaker to generate consistent film test cards for post-formulation studies.

B. Raw materials

Manufacturers of raw materials for the paint and Coatings industry, such as gluing agents, pigments, colorants, solvents, additives, and resins, require repeability film samples to determine the role of their products in their R & D laboratory formulations.

C. Battery research and development

The industry is eager to seek better, greener batteries. Thin-film technology plays an important role in this research. These labs use automated film machines to film, such as electrolysis on thin metal plates.

Ⅲ.How to Choose an Automatic Film Applicator?

A. Depends on the coating material

Wet Film Applicator for high viscosity, Mayer Rods for low viscosity. Generally, the lower end is used for heating, and the upper end is used for rapid drying.

B. determine the coating substrate

If the vacuum film cannot be adsorbed, pay special attention to the flat substrate; if it is a hard ground material such as Tinplate, it depends on the flatness and Roughness. If the substrate is too small, the Applicator cannot be used, because the Applicator depends on the height difference provided at both ends. In this case, it is recommended to choose a rod film Tester. However, if the viscosity is too high, NBCHAO can provide a test machine or a wire rod for trial. Generally, vacuum adsorption film is used; ordinary Glass plate is used as the film on Paper.

C. determine the coating size

It is important to confirm the required Spreader size (LxW) and then select the appropriate Automatic Film Applicator.

Generally speaking, Automatic Film Applicator is mainly used to reduce the error caused by artificial Spreader and improve the repeability effect. One difference between high-low-end products is the motor, and the other is the coated substrate. The flatness, Roughness and straightness of the substrate directly affect the accuracy and effect of the film, and the motor is mainly affected by factors such as vibration and service life. In order to reduce the vibration shock caused by the motor, many users will choose the Automatic Film Applicator with vacuum adsorption function and put the Vacuumpump outside, which can reduce the vibration of the Automatic Film Applicator itself. Of course, don't forget that the main core equipment for controlling the film accuracy is the film device or the wire rod. The accuracy of the film motor and the substrate is mainly to "reduce" the manual film error, and the control of the film thickness still has to rely on the high-precision film device.