The salt spray test is an accelerated corrosion test used to measure the relative corrosion resistance of materials exposed to salt spray or spray at elevated temperatures.

This corrosion test is designed to provide information on the corrosion resistance of metals and coated metals. Visual inspection after testing can determine the suitability of coatings, paints and metals to resist corrosion or be exposed to marine environments.

Salt spray test is also known as ASTM B117 and fog test.

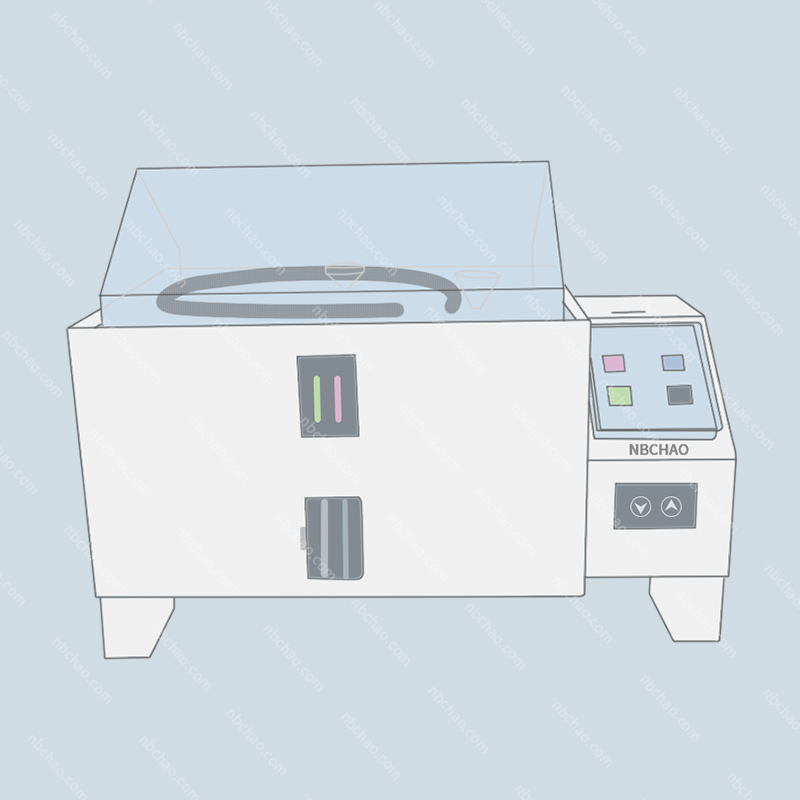

In the salt spray test, samples are placed in a closed salt spray test cabinet or chamber constructed in accordance with ASTM B117 specifications and subjected to uninterrupted spray of indirect fog or saline solution. This environment remained constant throughout the testing period. Chamber construction, test procedures and test parameters are standardized according to national and international standards such as ASTM B117 and ISO 9227.

Temperature maintained at 95°F (+34°F to 35°F) (35°C (+1.1°C to 1.7°C)), pH range 6.5 to 7.2, salt atmosphere 5 parts NaCl to 95 parts ASTM D1193 Type IV water, introduced into the chamber at a specific air pressure. This test does not determine the length of exposure.

The ASTM B117 salt spray test standard is widely used to measure normal corrosion resistance to seawater type environments. The test duration depends on the specification or corrosion resistance of the material.

Salt spray test is used for:

Correlates corrosion resistance of various metals or finishes

Measures the corrosive dip when a metal or coated surface is scratched

Determining Coating Adhesion and Corrosion Creep

Evaluation of corrosion resistance in marine environments (humidity, temperature, salt spray)

Salt spray testing is popular because it is well standardized and reasonably repeatable. Salt spray testing is widely used to evaluate the corrosion resistance of parts or finished surfaces in the following industries:

industry

seafood

car

aircraft and military equipment