Concept

Weathering resistance refers to the ability of a material or product to maintain its original performance and Appearance under different natural environment conditions, such as temperature, Humidity, UV rays, wind, rain, hail and other harsh climate erosion. Weathering resistance is an important material performance indicator, especially for materials and products in outdoor environments, such as building materials, automotive coatings, outdoor furniture, etc., its weathering performance requirements are higher.

When selecting industrial, commercial and residential structures and their building materials, paints and coatings, the particular challenges of certain climate conditions must be taken into account, ensuring that they can withstand adverse and harsh climate conditions. For example, exterior-wall materials can continuously protect the building from strong winds by employing a strong material. This material may also be able to withstand lower temperatures than the Miscellaneous form of exterior-wall materials. Temperatures and Humidity are higher in some areas, and this climate can cause mold and deterioration problems that can seriously damage the building structure. An example of good weather resistance is paints applied to automobiles, which can protect steel plates from harmful environmental conditions.

Industry

In different industries and fields, weathering resistance requirements and testing methods may vary. For example, in the construction industry, weathering resistance testing usually involves artificial accelerated aging testing of materials in the laboratory, such as ultraviolet exposure, temperature changes, etc., and outdoor exposure testing in the natural environment. For automotive coatings, weathering resistance testing may include durability testing under high temperature, low temperature, Humidity and other conditions. Generally, the quality of weathering resistance depends on the mass and composition of the material or product, as well as the influence of the external environment. To improve weathering performance, manufacturers may use different materials, formulations and processes to meet specific application requirements.

Application

Building materials: For example, steel structures, concrete, Stone, ceramic tiles and other building materials need to withstand the test of rain, sun, wind and other climate conditions, so they need to have strong weathering resistance.

Automotive coatings: Appearance color needs to be stable for a long time and can withstand the erosion of harsh climate conditions, such as ultraviolet rays, acid rain, high temperature, etc.

Plastic products: Plastic materials need to withstand natural light, humidity, heat, cold, ultraviolet and other environmental conditions, so they need to have good weathering resistance.

Metal materials: Metal products need to withstand oxidation, corrosion and other effects, such as zinc roofs, iron doors, etc. need to have strong weathering resistance.

Spinning & weaving products: Outdoor Spinning & weaving products need to be able to withstand the erosion of environmental conditions such as sun, rain and temperature changes, such as sun umbrellas, camping tents, etc.

In these fields, the weathering performance of materials or products often affects their service life and Appearance, so manufacturers and researchers need to fully consider and test their weathering resistance when designing and manufacturing.

Weathering resistance test

In general, weathering resistance testing requires different testing methods and equipment according to different materials and products and application scenarios. The following are some common weathering resistance testing methods:

Artificial accelerated aging test: The use of artificial equipment to simulate different factors in the natural environment, such as ultraviolet rays, heat, Humidity, acid rain, etc., to test materials and products. This test method can simulate the natural environment for many years in a short time to evaluate its weathering performance.

This test uses artificial equipment to simulate different factors in the natural environment, such as ultraviolet rays, heat, Humidity, acid rain, etc., to test materials and products.

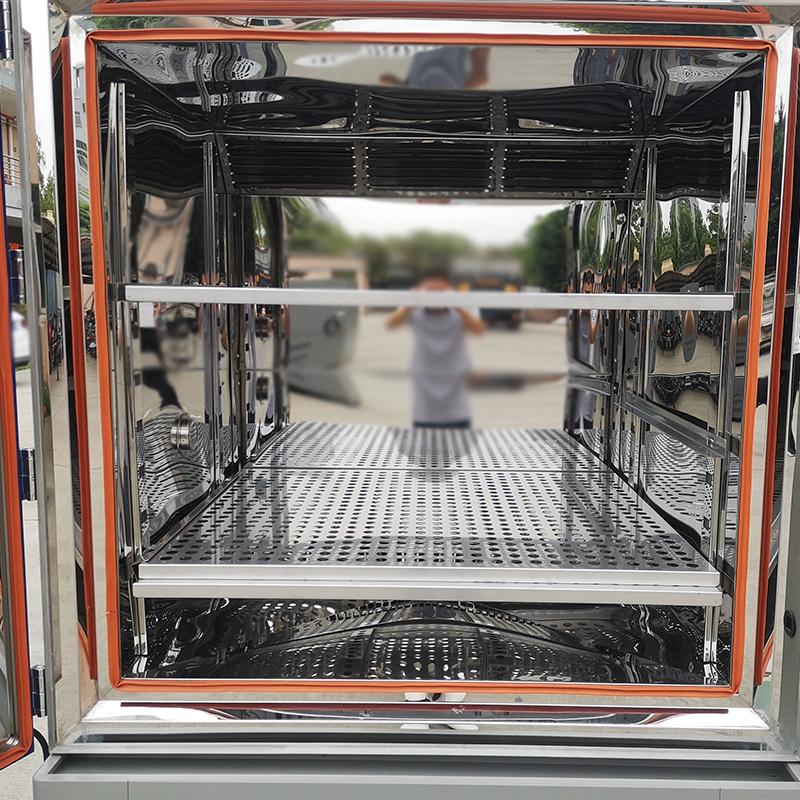

Using specialized testing equipment, such as UV aging boxes, heat and humidity circulation boxes, etc., it is possible to simulate the natural environment for many years in a short time to evaluate its weathering performance.

The test results can be evaluated by observing the changes in the surface of the material, measuring its mechanical properties, chemical properties and other indicators.

Natural exposure test: Expose materials or products to the natural environment, such as outdoor, seaside, alpine and other areas, and observe their durability and Appearance changes in the actual use environment.

Expose materials or products to the natural environment, such as outdoor, seaside, alpine and other areas, and observe their durability and Appearance changes in the actual use environment.

This test method is closer to the actual use case and can examine the performance of the material in different geographical and climate conditions.

The testing cycle is long, and it usually takes months or even years to obtain reliable test results.

Direct exposure test: directly expose materials or products to the external environment, such as sunlight, ultraviolet rays, acid rain, high temperature, etc., and evaluate their weathering performance by measuring their weight, size, surface change and other indicators.

Expose materials or products directly to the external environment, such as sunlight, ultraviolet rays, acid rain, high temperature, etc., and evaluate their weathering performance by measuring their weight, size, surface changes and other indicators.

This test method can simulate the performance changes of materials under specific environment conditions, such as surface aging in high temperature areas or under strong ultraviolet irradiation.

Through regular observation and measurement, the weathering performance of the material can be tracked over time.

Cyclic temperature change test: by placing the material or product in a high temperature and low temperature cycle environment to simulate the weathering performance of the material at different temperatures.

By placing the material or product in a high temperature and low temperature cycle environment, the weathering performance of the material at different temperatures can be simulated.

This test method can evaluate the performance of materials in environments with severe temperature changes, such as in areas with large temperature differences between day and night.

Test equipment typically includes a Temperature Control system and circulating blower to ensure Stability and repeatability of test conditions.

Salt spray test: Placing materials or products in a saline water environment to evaluate their corrosion resistance performance.

Place materials or products in a saline water environment to evaluate their corrosion resistance performance.

This test method is often used to evaluate the corrosion resistance performance of metallic materials, especially in marine environments or areas with corrosive climate conditions.

By observing the corrosion of the material surface and measuring its weight loss, its weathering performance and corrosion resistance can be evaluated.

These test methods require the use of professional equipment and laboratory conditions, and the appropriate test method needs to be selected according to the characteristics of different materials and products. Data analysis and evaluation are also required to determine whether the weathering performance of the material or product meets the requirements.