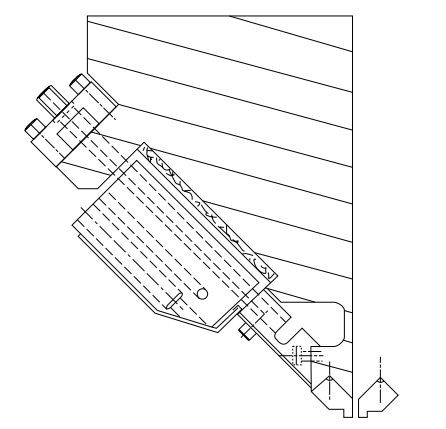

All currently commercially acceptable automatic die adjustment systems use a flexible lip and heat bolt arrangement (see Figure 20.12). There are minor differences in the details, but overall overall performance doesn't seem to be affected much. The larger confusion revolves around the effect of purely mechanical response time and its relationship to process analysis and its relationship to response. All systems to date have simply read changes in targets and responded correctively. Polymer batch-to-batch variability, temperature variations, plant airflow, and many other factors affecting metering make it impossible to predict flow variations. However, anticipation-based procedures can be used in product changes if the effects are known to occur within a relatively fixed period of time or at launch.

During a production run, if you notice a difference, make sure it's not a short-term effect that disappears in the time it takes to make the change. We might also want to determine the variance trend. Only by carefully analyzing the problem can the mold be adjusted. The time from discovery to adjustment effect will vary by production line, but startup to ±5% control (assuming the overall system has achieved some stability) will be 10 to 20 minutes and control to ±3% within 15 to 30 minutes.

Figure 20.12 Automatic transverse coat weight control.

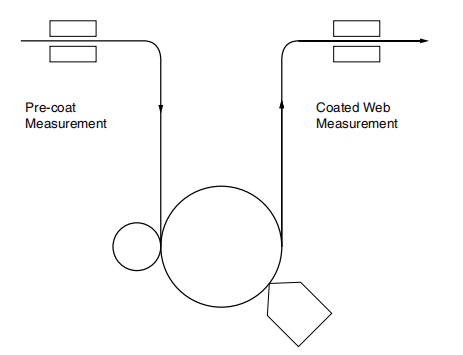

Separation of gross weight and substrate weight is achieved by a layout similar to that shown in Figure 20.13, which is the first step in the process control cycle. Existing technology is available and has been proven in production for almost a decade.

Autoflex dies feature thermal expansion and contraction of the lip adjustment bolts, allowing finer adjustments to the lip opening than strictly mechanical means.

Each lip adjuster bolt houses a block containing the heater and air cooling paths. Before using the Autoflex system, establish approximate gauge uniformity in a conventional manner.

Figure 20.13 Schematic diagram of the separation of gross weight and substrate weight in the production control cycle

Thickness variations are translated into lip opening corrections by increasing or decreasing power to individual lip bolt control blocks to minimize variation.

The key to transverse thickness control is a microprocessor-based controller that interfaces with a conventional computer control system.

On ambient run molds, care needs to be taken to isolate the Autoflex bolts from the heat of the mold body.

Die-to-roll position adjustment system

The importance of the ability to repeat the original roll to die set position during start-up and normal web splice coating interruptions cannot be overemphasized.

During operation, minor changes in die position may be required to accommodate roll expansion, changes in adhesive viscosity and smoothness, and changes in substrate thickness. An automatic positioning device is available which will allow continuous adjustment of the web to the lip if required.

This is accomplished with equipment similar to the Autoflex die bolt adjustment system. Heating and cooling units are installed in a manual adjustment system (US Patent 3,940,221) for setting the die-to-roll gap. Heating or cooling of the unit will expand or contract the steel block and increase or decrease the die-to-roll gap. Requires an available method for monitoring smoothness and interface to the Autoflex computer.