paste paint

Fine or thin coats are in the dry application weight range of 5 to 25 g/m2. The sorters used were 80 mesh 12% open area, 100 mesh SP (special) 20% open area and 125 mesh SP 12% open area, 130 μm thickness (for reference only).

End uses include windbreakers, skiwear, sportswear, raincoats, umbrellas, pressure sensitive coatings (medical) and quick transfer coatings.

Medium coats have a dry weight in the range of 15 to 20 g/m2. The screens used were 60 mesh LR (long term) 14% open area, 125 μm thick, and 40 mesh LR 20% open area, 130 μm thick.

End uses include roller blinds, aluminum coated drapes, bag material and ironing rod covers.

Heavy overcoats with a dry coating weight of 15 to 130 g/m2 are often applied using a 40 mesh HX (hexagonal) screen with an open area of 30% and a thickness of 300 μm. End uses include vertical blinds, flame retardant coatings on upholstery and technical coatings, and tablecloths.

The repeat size for size coated screens is always 64 cm (25 in).

The scraper blade is 28 mm × 0.2 mm.

foam paint

When the coating is applied via thermally unstable foam (foam collapses in the dryer/stenter) or stable foam, only three types of screens are suitable:

1. 40 mesh HX (50% open area, 300 μm thick, 91.4 cm [35.8 in.] repeats), for foam coatings with a dry weight of 20 to 60 g/m2

2. 14 mesh HX (40% open area, 450 μm thick, 91.4 cm [35.9 in.] repeats), for foam coatings with a dry weight of 50 to 100 g/m2

3. 25 mesh HX (30% open area, 350 μm thick, 91.4 cm [35.9 in.] repeat) for average foam coatings

The stabilized foam is applied by means of a spatula 40 mm wide and 0.2 mm thick.

End uses include blackout or roller blinds, breathable coatings for windbreakers and raincoats, and flocking adhesives on drapes and shower curtains.

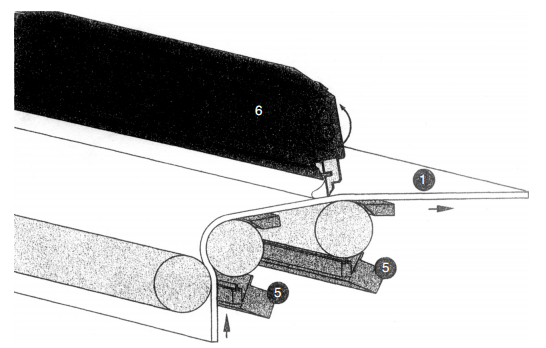

Thermally unstable foam coatings are applied directly through a "closed" system (see Figure 23.2) through a foam handler and closed drawdown blade through a wire mesh on the fabric. Wet coat weight can be adjusted on the foam handler.

Figure 23.3 Adaptation of screen coater to blade coating

For example, to use 30 g/m2 dry acrylic or polyurethane adhesive (50% solids), simply adjust the wet application weight on the foam handler to 60 g/m2.

End uses include velor back coatings, automotive back coatings, mattress ticking, fastening of pile fabrics, flame and cigarette resistant coatings, suede and anti-slip coatings.