1. Coating can be done without tension and friction because the substrate, screen and counter pressure roller have the same speed. As a result, almost all substrates can be processed on the system, including knitted fabrics, velvets, nonwovens and shift-sensitive materials such as ski suits, mattresses and Lycra fabrics.

2. The user has penetration control: penetration into the substrate can be avoided entirely, or, if desired, can be controlled.

3. Due to the low content of the system, the coating method is clean and can be replaced quickly.

4. The coating is fully reproducible. As parameters, drawdown blade pressure, drawdown blade settings, mesh and viscosity can be measured and read, and any given coating can be easily repeated.

5. Savings in chemicals (up to 20% of coating weight) are achieved in two ways: (a) by precisely controlled overfeeding), which should be avoided when using drawdown blade coatings); (b) high precision through the amount of application in the left/right and longitudinal directions.

6. Apply with neither tension nor friction.

7. Through the closed system, the user can control the whole process.

8. The drawdown blade coating option can be installed above the aforementioned whisper blade roll.

This knife coater (see Figure 23.3) can be used as a knife air system for pasty or erratic foam coatings, as well as with knife roller coaters manufactured for foam applications. In both cases, the equipment is equipped with a slurry or foam distribution system over the entire working width. In this way, colored coatings can be applied with a completely uniform appearance.

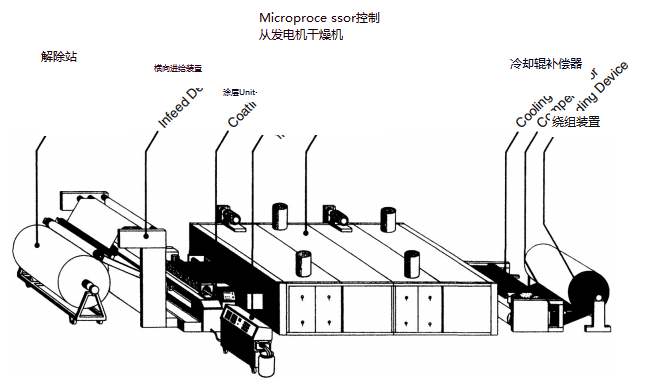

A schematic diagram of a rotary screen coating line is shown in Figure 23.4.

Figure 23.4 Screen coating line